Mitsubishi Outlander: Power Plant Mount

General Information

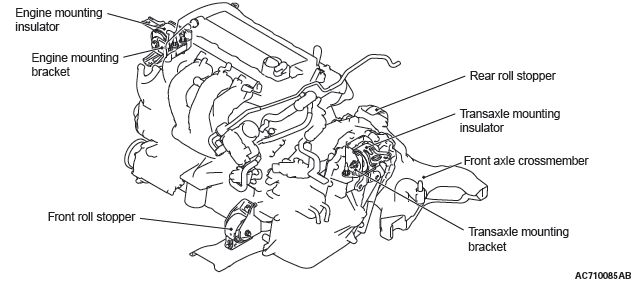

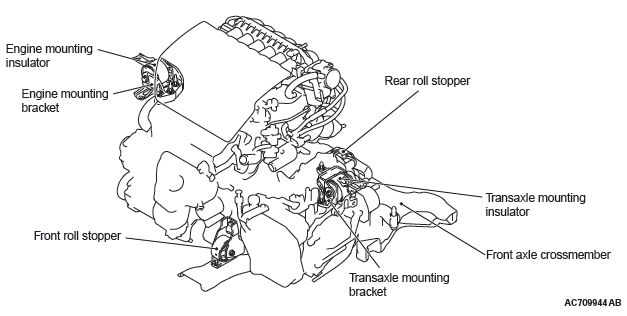

For the power plant support, the inertial axis four-point mounting system is utilized, and the system has the following features.

- For the engine and transaxle mountings, the cylindrical liquid seal mountings are used. This reduces idling vibration and acceleration noise, and improves riding comfort.

- For the engine mounting bracket, light weight and high rigidity aluminum is used to reduce acceleration noise.

- For the transaxle mounting bracket, light weight and high rigidity sheet metal is used to reduce gear noise.

- For the front and rear roll stoppers, insulators developed for CVT <2.4L ENGINE> or A/T <3.0L ENGINE> are utilized. This reduces idling vibration and acceleration/deceleration shock.

- A front axle crossmember improves steering ability.

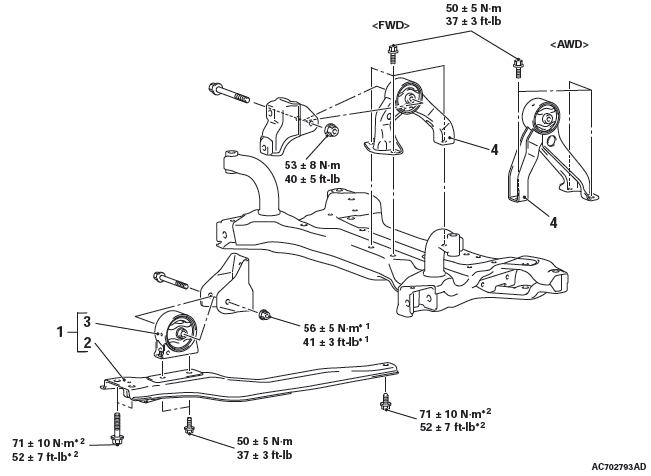

CONSTRUCTION DIAGRAM

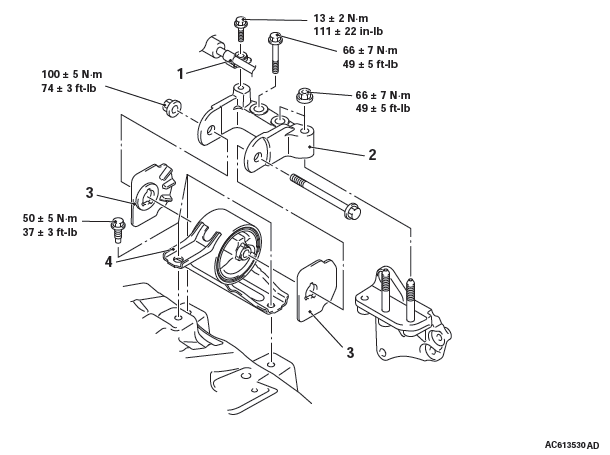

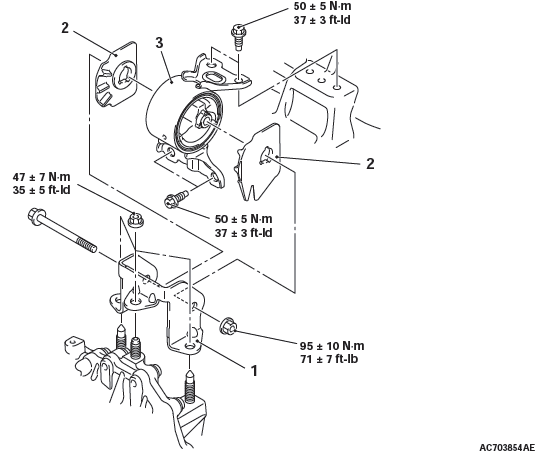

<2.4L ENGINE>

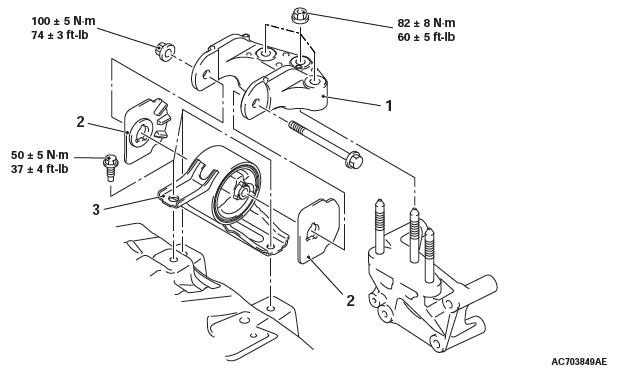

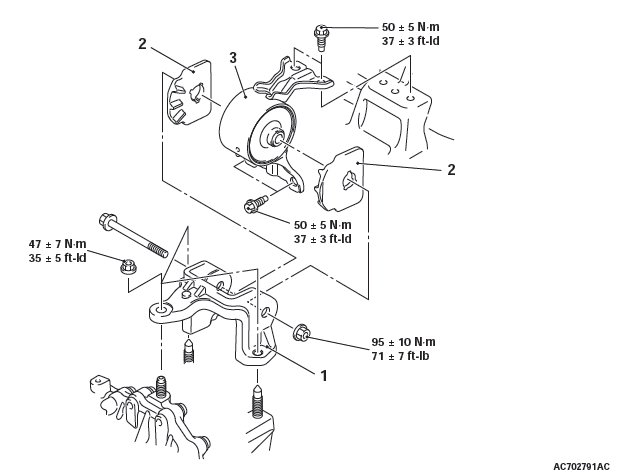

<3.0L ENGINE>

Special Tool

Engine Mounting

REMOVAL AND INSTALLATION <2.4L ENGINE>

Pre-removal Operation

- Radiator Condenser Tank Removal

- Power Steering Oil Pump Removal

Post-installation Operation

- Power Steering Oil Pump Installation

- Radiator Condenser Tank Installation

Removal steps

- Power steering pressure hose clamp

- Engine mounting bracket

- Engine mounting insulator stopper

- Engine mounting insulator

REMOVAL SERVICE POINT

ENGINE MOUNTING BRACKET REMOVAL

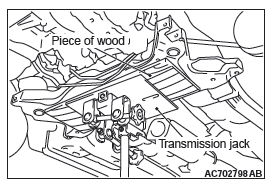

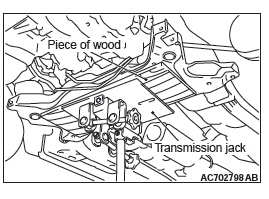

CAUTION When supporting the engine and transaxle assembly with a garage jack, be careful not to deform the engine oil pan.

1. Place a garage jack against the engine oil pan with a piece of wood in between to support the engine and transaxle assembly.

2. Operate a garage jack so that the engine weight is not applied to the engine mounting insulator, and remove the engine mounting insulator.

INSTALLATION SERVICE POINT

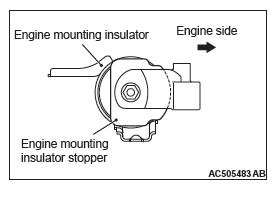

ENGINE MOUNTING INSULATOR STOPPER INSTALLATION

Install the engine mounting insulator stopper as shown in the figure.

REMOVAL AND INSTALLATION <3.0L ENGINE>

Pre-removal operation

- Radiator Condenser Tank Removal

Post-installation operation

- Radiator Condenser Tank Installation

Removal steps

- Engine mounting bracket

- Engine mounting insulator stopper

- Engine mounting insulator

REMOVAL SERVICE POINT

ENGINE MOUNTING BRACKET REMOVAL

CAUTION When supporting the engine and transaxle assembly with a garage jack, be careful not to deform the engine oil pan.

1. Place a garage jack against the engine oil pan with a piece of wood in between to support the engine and transaxle assembly.

2. Operate a garage jack so that the engine weight is not applied to the engine mounting insulator, and remove the engine mounting insulator.

INSTALLATION SERVICE POINT

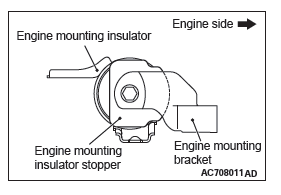

ENGINE MOUNTING INSULATOR STOPPER INSTALLATION

Install the engine mounting insulator stopper as shown in the figure.

Transaxle Mounting

REMOVAL AND INSTALLATION <2.4L ENGINE>

Pre-removal operation

- Battery and Battery Tray Removal

- Air Cleaner Assembly Removal

- Engine Control Module (ECM) Removal

Post-installation operation

- Engine Control Module (ECM) Installation

- Air Cleaner Assembly Installation

- Battery and Battery Tray Installation

Removal steps

- Transaxle mounting bracket

- Front roll stopper and centermember assembly

- Transfer assembly <AWD>

- Transaxle mounting insulator stopper

- Transaxle mounting insulator

REMOVAL SERVICE POINT

TRANSAXLE MOUNTING BRACKET REMOVAL

1. Place a garage jack against the transaxle case with a piece of wood in between to support the engine and transaxle assembly.

2. Operate a garage jack so that the transaxle weight is not applied to the transaxle mounting insulator, and remove the transaxle mounting bracket.

INSTALLATION SERVICE POINT

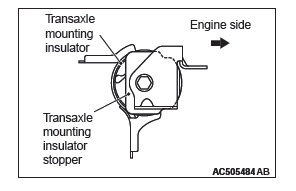

TRANSAXLE MOUNTING INSULATOR STOPPER INSTALLATION

Install the transaxle mounting insulator stopper as shown in the figure.

REMOVAL AND INSTALLATION <3.0L ENGINE>

Pre-removal operation

- Battery and Battery Tray Removal

- Air Cleaner Assembly Removal

- Engine Control Module (ECM) Removal

Post-installation operation

- Engine Control Module (ECM) Installation

- Air Cleaner Assembly Installation

- Battery and Battery Tray Installation

Removal steps

- Transaxle mounting bracket

- Front roll stopper and centermember assembly

- Transfer assembly <AWD>

- Transaxle mounting insulator stopper

- Transaxle mounting insulator

REMOVAL SERVICE POINT

TRANSAXLE MOUNTING BRACKET REMOVAL

1. Place a garage jack against the transaxle case with a piece of wood in between to support the engine and V assembly.

2. Operate a garage jack so that the transaxle weight is not applied to the transaxle mounting insulator, and remove the transaxle mounting bracket.

INSTALLATION SERVICE POINT

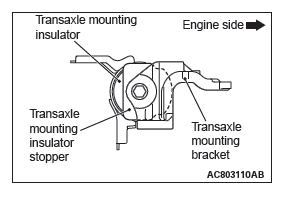

TRANSAXLE MOUNTING INSULATOR STOPPER INSTALLATION

Install the transaxle mounting insulator stopper as shown in the figure.

Engine Roll Stopper and Centermember

REMOVAL AND INSTALLATION

CAUTION

- When the engine mounting insulator, transaxle mounting insulator and rear roll stopper have been removed, tighten the engine mounting insulator, transaxle mounting insulator and rear roll stopper securely. Then, tighten the front roll stopper center nut *1 securely.

- The parts indicated by the *2 are the bolts with friction coefficient stabilizer. In removal, ensure there is no damage, clean dust and soiling from bearing and thread surfaces, and tighten them to the specified torque.

Pre-removal and post-installation operation

- Engine Room Under Cover Front A<AWD>, B, and C Removal

and Installation (Refer to GROUP 51, Under Cover).

<2.4L ENGINE>

- Engine Room Under Cover Front Removal and Installation (Refer to GROUP 51, Under Cover). <3.0L ENGINE>

Front roll stopper and centermember removal steps

- Front roll stopper and centermember assembly

- Centermember

- Front roll stopper

Rear roll stopper removal steps

- Transfer assembly <AWD>

- Rear roll stopper

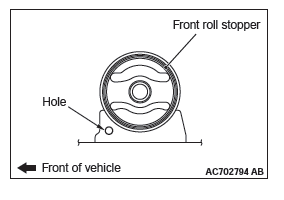

INSTALLATION SERVICE POINT

FRONT ROLL STOPPER INSTALLATION

Install the front roll stopper so that the hole faces toward the vehicle front.

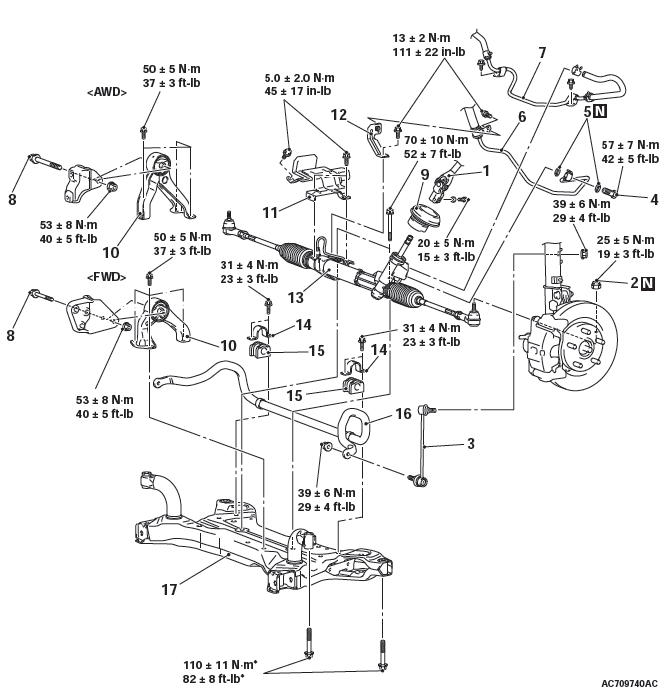

Crossmember

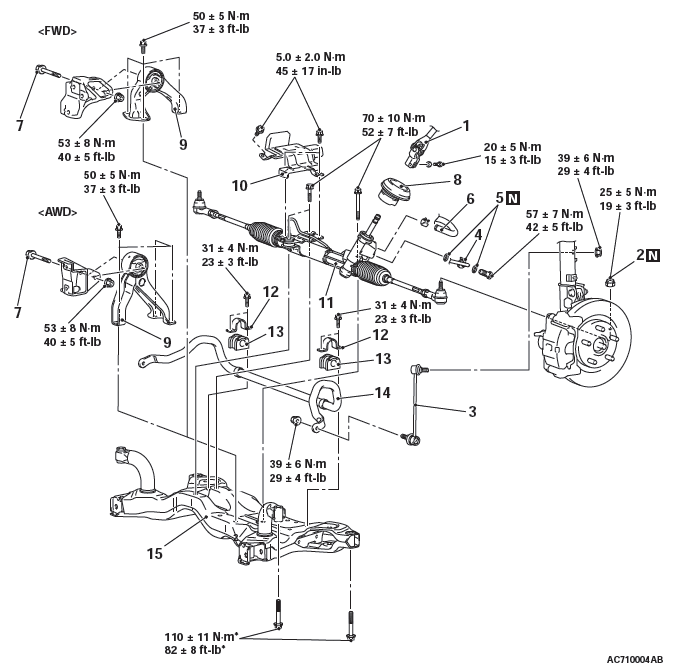

REMOVAL AND INSTALLATION <2.4L ENGINE>

CAUTION

- Before replacing the steering wheel assembly and driver's air bag module assembly, always refer to GROUP 52B, Service Precautions, and Air Bag Module(s) and Clock Spring. Also, position the front wheels in a straight ahead direction, and remove the ignition key. If you fail to do this, clock spring for SRS may get damage, making the SRS (air bag) inoperative, and it may cause a serious injury to the driver.

- The parts indicated by * are the bolts/nuts with friction coefficient stabilizer. In removal, ensure there is no damage, clean dust and soiling from the bearing and thread surfaces, and tighten them to the specified torque.

- After installation, perform calibration to make ASC-ECU learn the neutral position of the steering wheel sensor.

Pre-removal operation

- Steering Wheel and Air Bag Module Assembly Removal

- Footrest Removal

- Front Roll Stopper and Centermember Assembly

- Power Steering Fluid Drain

- Engine Room Under Cover A<AWD>, B, C and Engine Room Side Cover Removal

- Lower Arm Assembly Removal

Post-installation operation

- Using Your Fingers, Press The Tie-rod End Ball Joint Dust Cover To Check for a Crack or Damage

- Using Your Fingers, Press The Stabilizer Link Ball Joint Dust Cover To Check for a Crack or Damage

- Lower Arm Assembly Installation

- Front Roll Stopper and Centermember Assembly Installation

- Engine Room Under Cover A<AWD>, B, C and Engine Room Side Cover Installation

- Footrest Installation.

- Clock Spring Centering

- Steering Wheel Air Bag Module Assembly Installation

- Power Steering Fluid Refilling and Bleeding

- Steering Wheel Straight-ahead Position Check

- Front Wheel Alignment Check and Adjustment

Removal steps

- Steering column shaft assembly connection

- Self-lock nut (Tie-rod end and knuckle connection)

- Stabilizer link assembly

- Eye bolt

- Gasket

- Pressure hose assembly

- Return hose connection

- Rear roll stopper center bolt

- Front axle crossmember assembly

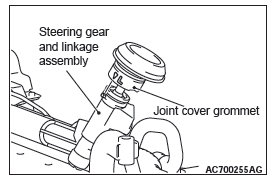

- Joint cover grommet

- Rear roll stopper

- Heat protector

- Bracket

- Steering gear and linkage assembly

- Stabilizer bar bracket

- Stabilizer bushing

- Stabilizer bar

- Front axle crossmember

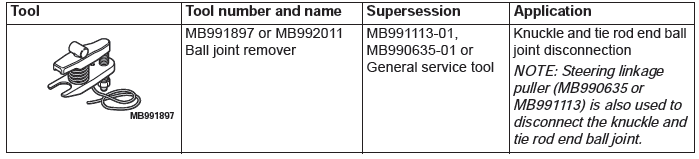

Required Special Tool:

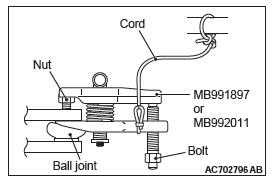

- MB991897 or MB992011: Ball Joint Remover

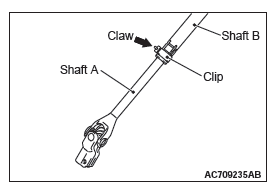

REMOVAL SERVICE POINTS

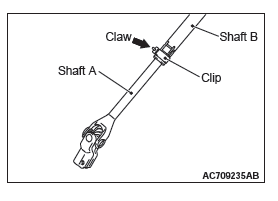

STEERING COLUMN SHAFT ASSEMBLY CONNECTION DISCONNECTION

Disconnect the steering gear and linkage assembly from the steering column shaft assembly while sliding the shaft A to the shaft B with the clip claw as shown in the figure is pinched.

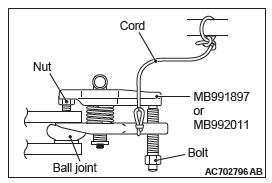

SELF-LOCK NUT (TIE-ROD END AND KNUCKLE CONNECTION) REMOVAL

CAUTION

- Loosen the self-locking nut from the ball joint, but do not remove here. Use the special tool.

- To prevent the special tool from dropping off, suspend it with a cord.

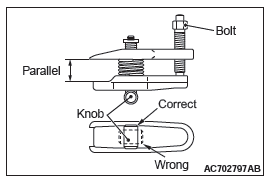

1. Install the special tool MB991897or MB992011 as shown in the figure.

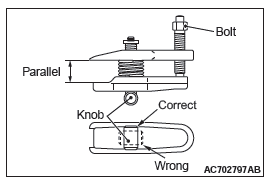

2. Turn the bolt and knob to make the special tool jaws parallel, then hand-tighten the bolt. After tightening, check that the jaws are still parallel.

NOTE: To adjust the special tool jaws to be parallel, set the knob as shown in the figure so that it functions as a fulcrum of the jaws.

3. Turn the bolt and disconnect the tie-rod end from the steering knuckle.

FRONT AXLE CROSSMEMBER ASSEMBLY REMOVAL

1. Jack up and support the front axle crossmember assembly, and remove it.

2. Check the hoses and harnesses for roughness, and then remove the front axle crossmember assembly with the rear roll stopper and the steering gear and linkage assembly installed.

INSTALLATION SERVICE POINTS

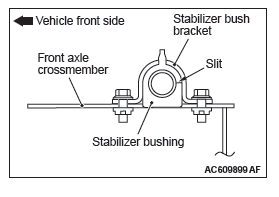

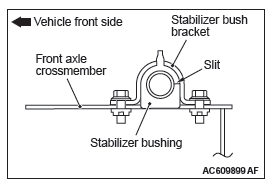

STABILIZER BAR/STABILIZER BUSHING/ STABILIZER BAR BRACKET INSTALLATION

Install the stabilizer bar, the stabilizer bushing and the stabilizer bar bracket as shown in the figure.

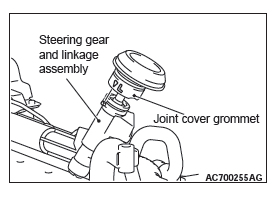

JOINT COVER GROMMET INSTALLATION

Install the joint cover grommet to the steering gear and linkage assembly by aligning the mating marks as shown in the figure.

REMOVAL AND INSTALLATION <3.0L ENGINE>

CAUTION

- Before replacing the steering wheel assembly and driver's air bag module assembly, always refer to GROUP 52B, Service Precautions, and Air Bag Module(s) and Clock Spring. Also, position the front wheels in a straight ahead direction, and remove the ignition key. If you fail to do this, clock spring for SRS may get damage, making the SRS (air bag) inoperative, and it may cause a serious injury to the driver.

- The parts indicated by * are the bolts/nuts with friction coefficient stabilizer. In removal, ensure there is no damage, clean dust and soiling from the bearing and thread surfaces, and tighten them to the specified torque.

- After installation, perform calibration to make ASC-ECU learn the neutral position of the steering wheel sensor.

Pre-removal operation

- Steering Wheel Air Bag Module Assembly Removal

- Footrest Removal

- Front Exhaust Pipe Removal

- Front Roll Stopper and Centermember Assembly Removal

- Power Steering Fluid Drain

- Engine Room Under Cover Front and Engine Room Side Cover Removal

- Lower Arm Assembly Removal

Post-installation operation

- Using Your Fingers, Press The Tie-rod End Ball Joint Dust Cover To Check for a Crack or Damage

- Using Your Fingers, Press The Stabilizer Link Ball Joint Dust Cover To Check for a Crack or Damage

- Lower Arm Assembly Installation

- Front Roll Stopper and Centermember Assembly Installation

- Engine Room Under Cover Front and Engine Room Side Cover Installation

- Footrest Installation

- Front Exhaust Pipe Installation

- Clock Spring Centering

- Steering Wheel Air Bag Module Assembly Installation

- Power Steering Fluid Refilling and Bleeding

- Steering Wheel Straight-ahead Position Check

- Front Wheel Alignment Check and Adjustment

Removal steps

- Steering gear and joint connecting bolt

- Self-lock nut (Tie-rod end and knuckle connection)

- Stabilizer link assembly

- Pressure hose connection

- Gasket

- Return hose connection

- Rear roll stopper center bolt

- Front axle crossmember assembly

- Joint cover grommet

- Rear roll stopper

- Heat protector

- Steering gear and linkage assembly

- Stabilizer bar bracket

- Stabilizer bushing

- Stabilizer bar

- Front axle crossmember

Required Special Tool:

- MB991897 or MB992011: Ball Joint Remover

REMOVAL SERVICE POINTS

STEERING COLUMN SHAFT ASSEMBLY CONNECTION DISCONNECTION

Disconnect the steering gear from the steering column assembly while sliding the shaft A to the shaft B with the clip claw as shown in the figure is pinched.

SELF-LOCK NUT (TIE-ROD END AND KNUCKLE CONNECTION) REMOVAL

CAUTION

- Loosen the self-locking nut from the ball joint, but do not remove here. Use the special tool.

- To prevent the special tool from dropping off, suspend it with a cord.

1. Install the special tool MB991897or MB992011 as shown in the figure.

2. Turn the bolt and knob to make the special tool jaws parallel, then hand-tighten the bolt. After tightening, check that the jaws are still parallel.

NOTE: To adjust the special tool jaws to be parallel, set the knob as shown in the figure so that it functions as a fulcrum of the jaws.

3. Turn the bolt and disconnect the tie-rod end from the steering knuckle.

FRONT AXLE CROSSMEMBER ASSEMBLY REMOVAL

1. Jack up and support the front axle crossmember assembly, and remove it.

2. Check the hoses and harnesses for roughness, and then remove the front axle crossmember assembly with the rear roll stopper and the steering gear and linkage assembly installed.

INSTALLATION SERVICE POINTS

STABILIZER BAR/STABILIZER BUSHING/ STABILIZER BAR BRACKET INSTALLATION

Install the stabilizer bar, the stabilizer bushing and the stabilizer bar bracket as shown in the figure.

JOINT COVER GROMMET INSTALLATION

Install the joint cover grommet to the steering gear and linkage assembly by aligning the mating marks as shown in the figure.