Mitsubishi Outlander: Rear Wiper and Washer

GENERAL INFORMATION

REAR WIPER AND WASHER

REAR WIPER OPERATION

- If the rear wiper and washer switch is turned to the "INT" position with the ignition switch at "ACC" or "ON" position, the ETACS-ECU causes the rear wiper to operate continuously 2 times, then intermittently at 8-second intervals.

- If the selector lever (or gearshift lever) is moved to the "R" position when the rear wiper and washer switch is turned to the "INT" position and the ignition switch at "ACC" or "ON" position, the transmission range switch (or backup light switch) "R" turns ON. 1 second later, the ETACS-ECU causes the rear wiper to operate continuously 2 times to ensure good rearward visibility. The ETACS-ECU then causes the rear wiper to operate intermittently again at 8-second intervals.

REAR WASHER OPERATION

- If the rear wiper and washer switch is turned to the ON (washer) position with the ignition switch at "ACC" or "ON" position, the rear washer ON signal is sent to the ETACS-ECU, causing the rear wiper signal to turn on after 0.9 second. After the rear washer switch signal turns off, the rear wiper signal turns off in 3 seconds.

- If the rear wiper and washer switch is turned to

the ON (washer) position while the rear wiper is

at intermittent mode, the rear washer works for

that period when the washer switch remains on.

Then the rear wiper returns to the intermittent mode.

DESCRIPTION OF CONSTRUCTION AND OPERATION

Rear wiper control [Initial condition: 8 seconds (without successive operations) ]

1. When the rear wiper switch on the column switch is turned ON while the ignition switch is in ACC or ON position, ETACS turns the rear wiper relay ON for 3 seconds (for approximately 2 cycles) and operates the intermittent action in 8 seconds interval.

When the selector lever is moved to R (reverse) position during the rear wiper operation, the transmission range switch R (reverse) turns ON, and one second after that, ETACS turns the rear wiper relay ON for 3 seconds (for approximately 2 cycles), and operates the intermittent action in 8 seconds interval again.

2. By the special operation of the rear wiper switch on the column switch (2 consecutive operations), the rear wiper can operate continuously regardless on the set intermittent time.

NOTE: Using the customization function, the rear wiper intermittent time can be adjusted.

Rear wiper linked with washer function Initial condition: with function

When the rear washer switch on the column switch is turned ON while the ignition switch is in ACC or ON position, ETACS turns the rear washer relay ON.

The rear washer relay turns ON after the rear washer switch has been ON for 0.3 seconds, then turns the rear wiper relay ON to operate the rear wiper simultaneously.

When the rear washer switch is turned OFF, after 3 seconds the rear wiper is turned OFF.

If the rear washer switch is turned ON during the rear wiper operation, 7.4 seconds after turning OFF the rear wiper relay turns OFF, the intermittent action is resumed in 8 seconds interval.

NOTE: Using the customization function, the washer linked rear wiper function can be invalidated.

SPECIAL TOOL

REAR WIPER AND WASHER DIAGNOSIS

TROUBLESHOOTING STRATEGY

Gather the information from the customer.

1. Verify that the condition described by the customer exists.

2. Find the malfunction by the following Symptom Chart.

3. Verify the malfunction is eliminated.

TROUBLE SYMPTOM CHART

SYMPTOM PROCEDURES

INSPECTION PROCEDURE 1: Rear wiper does not work at all.

Rear Wiper Motor Circuit

CIRCUIT OPERATION

- The rear wiper switch sends a signal through the column-ECU (incorporated in the column switch) to the ETACS-ECU. If the column-ECU sends a rear wiper switch "ON" signal to the ETACS-ECU, the ETACS-ECU turns on the relay (incorporated in the ETACS-ECU), thus causing the rear wiper motor to be turned on.

- The ETACS-ECU operates the rear wiper according

to the following switches:

- Ignition switch (ACC)

- Rear wiper switch

TECHNICAL DESCRIPTION (COMMENT)

If the rear wiper does not work normally, the input circuit system from the switches, the rear wiper motor, the column switch (windshield wiper and windshield washer switch) or the ETACS-ECU may be defective.

TROUBLESHOOTING HINTS

- The rear wiper motor may be defective

- The column switch (windshield wiper and washer switch) may be defective

- The ETACS-ECU may be defective

- The wiring harness may be damaged or the connectors may have loose, corroded or damaged terminals, pushed back in the connector

DIAGNOSIS

Required Special Tools:

- MB991223: Harness Set

- MB992006: Extra Fine Probe

- MB991958: Scan Tool (M.U.T.-III Sub Assembly)

- MB991824: Vehicles communication interface (V.C.I.)

- MB991827: M.U.T.-III USB cable

- MB991911: M.U.T.-III Main harness B

STEP 1. Use the scan tool MB991958 to check if an ETACS-related diagnostic trouble code is set.

Connect the scan tool.

Q: Is the diagnostic trouble code set?

YES : Diagnose the ETACS-ECU.

NO : Go to Step 2.

STEP 2. Check the input signal related to the rear wiper operation.

- Ignition switch: ACC

OK: Normal condition is displayed.

Q: Is the check result normal?

NO : Go to Step 3.

YES : Refer to GROUP 54A − ETACS, Input signal procedure.

STEP 3. Check the rear wiper motor connector F-04 for loose, corroded or damaged terminals, or terminals pushed back in the connector.

Q: Is rear wiper motor connector F-04 in good condition?

YES : Go to Step 4.

NO : Repair or replace the damaged component(s). Verify that the rear wiper works normally.

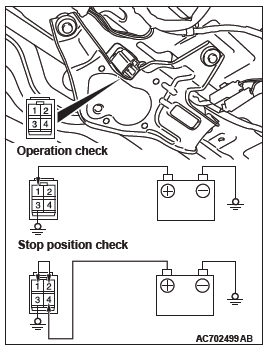

STEP 4. Check the rear wiper motor.

- Disconnect rear wiper motor connector F-04.

- Connect a battery to the wiper motor as shown in the illustration and inspect the motor operation.

Q: Is the rear wiper motor in good condition?

YES : Go to Step 5.

NO : Replace the rear wiper motor. Verify that the rear wiper works normally.

STEP 5. Check the ground circuit to the rear wiper motor.

Measure the resistance at the rear wiper motor connector F-04.

- Disconnect rear wiper motor connector F-04 and measure the resistance available at the wiring harness side of the connector.

- Measure the resistance value between terminal 3 and ground.

- The resistance should be 2 Ω or less.

Q: Is the measured resistance 2 Ω or less?

YES : Go to Step 7.

NO : Go to Step 6.

STEP 6. Check the wiring harness between rear wiper motor connector F-04 (terminal 3) and ground.

Q: Is the wiring harness between rear wiper motor connector F-04 (terminal 3) and ground in good condition?

YES : No action is necessary and testing is complete.

NO : The wiring harness may be damaged or the connector(s) may have loose, corroded or damaged terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Verify that the rear wiper works normally.

STEP 7. Check ETACS-ECU connector C-311 for loose, corroded or damaged terminals, or terminals pushed back in the connector.

Q: Is ETACS-ECU connector C-311 in good condition?

YES : Go to Step 8.

NO : Repair or replace the damaged component(s). Verify that the rear wiper works normally.

STEP 8. Check the wiring harness between rear wiper motor connector F-04 (terminal 1) and ETACS-ECU connector C-311 (terminal 5).

NOTE: Also check junction block connector D-12 for loose, corroded or damaged terminals, or terminals pushed back in the connector. Repair or replace the damaged component(s) as described in GROUP 00E, Harness Connector Inspection.

Q: Is the wiring harness between rear wiper motor connector F-04 (terminal 1) and ETACS-ECU connector C-311 (terminal 5) in good condition?

YES : Replace the ETACS-ECU. Verify that the rear wiper works normally.

NO : The wiring harness may be damaged or the connector(s) may have loose, corroded or damaged terminals, or terminals pushed back in the connector.

Repair the wiring harness as necessary. Verify that the rear wiper works normally.

INSPECTION PROCEDURE 2: Rear wiper does not stop at the specified park position.

Rear Wiper Motor Circuit

TECHNICAL DESCRIPTION (COMMENT)

If the rear wipers do not stop at predetermined park position, the rear wiper motor or the ETACS-ECU may be defective.

TROUBLESHOOTING HINTS

- The rear wiper motor may be defective

- The ETACS-ECU may be defective

- The wiring harness or connectors may have loose, corroded, or damaged terminals, or terminals pushed back in the connector

DIAGNOSIS

Required Special Tools:

- MB991223: Harness Set

- MB992006: Extra Fine Probe

STEP1. Check rear wiper motor connector F-04 for loose, corroded or damaged terminals, or terminals pushed back in the connector.

Q: Is rear wiper motor connector F-04 in good condition?

YES : Go to Step 2.

NO : Repair or replace the damaged component(s). Verify that the windshield wiper works normally.

STEP 2. Check the rear wiper motor.

- Disconnect rear wiper motor connector F-04.

- Connect the vehicle battery to the rear wiper motor connector as shown, and operate the rear wiper. While the rear wiper is working, disconnect the battery at positions other than the specified park position to stop the rear wiper motor.

- When the battery is connected as shown, the motor should run and then stop at the specified park position.

Q: Does the rear wiper motor operate normally?

YES : Go to Step 3.

NO : Replace the rear wiper motor. The rear wiper should now stop at the specified park position.

STEP 3. Check rear wiper motor connector F-04 and ETACS-ECU connector C-311 for loose, corroded or damaged terminals, or terminals pushed back in the connector.

Q: Is rear wiper motor connector F-04 and ETACS-ECU connector C-311 in good condition?

YES : Go to Step 4.

NO : Repair or replace the damaged component(s).

STEP 4. Check the wiring harness between rear wiper motor connector F-04 (terminals 2,4) and ETACS-ECU connector C-311 (terminals 8, 4).

NOTE: Also check intermediate connector D-12 for loose, corroded or damaged terminals, or terminals pushed back in the connector.

Q: Is the wiring harness between rear wiper motor connector F-04 (terminals 2,4) and ETACS-ECU connector C-311 (terminals 8, 4) in good condition?

YES : Go to Step 5.

NO : Repair or replace the damaged component(s).

STEP 5. Check the input signal related to the rear wiper operation.

- Ignition switch: ACC or ON

- Rear wiper: In operation

NOTE: Confirm that the scan tool displays ON to OFF when rear wiper stops at the specified park position.

OK: Normal condition is displayed.

Q: Is the check result normal?

YES : Intermittent malfunction. NO : Replace the ETACS-ECU.

INSPECTION PROCEDURE 3: When the selector lever is moved to "R" position during the rear wiper operation, the rear wiper does not operate at the continuous mode.

"R" Position During Wiper Operation Circuit

CIRCUIT OPERATION

The ETACS-ECU operates the rear wiper consecutively when the selector lever is moved to "R" position while the rear wiper is turned on.

TECHNICAL DESCRIPTION (COMMENT)

If the rear wiper does not work consecutively, the transmission range switch ("R" position) or the ETACS-ECU may be defective.

TROUBLESHOOTING HINTS

- The back-up light switch may be defective

- The ETACS-ECU may be defective

- The wiring harness may be damaged or the connectors may have loose, corroded or damaged terminals, pushed back in the connector

DIAGNOSIS

Required Special Tools:

- MB991223: Harness Set

- MB992006: Extra Fine Probe

- MB991958: Scan Tool (M.U.T.-III Sub Assembly)

- MB991824: Vehicles communication interface (V.C.I.)

- MB991827: M.U.T.-III USB cable

- MB991911: M.U.T.-III Main harness B

STEP 1. Verify the rear wiper.

Check that the rear wiper system works normally by operating the rear wiper switch.

Q: Does the rear wiper operate?

YES : Go to Step 2.

NO <Rear wiper does not work.> : Refer to Inspection Procedure 1 "Rear wiper does not work at all P.51"

STEP 2. Use the scan tool MB991958 to diagnose the CAN bus lines.

Connect the scan tool. Q: Is the check result normal?

YES : Go to Step 3.

NO : Repair the CAN bus line.

STEP 3. Use the scan tool MB991958 to diagnose other system diagnostic trouble code

Connect the scan tool. Check that the TCM sets a bus-off diagnostic trouble code.

Q: Is the diagnostic trouble code set?

YES : A poor connection, open circuit or other intermittent malfunction is present in the CAN bus lines between the TCM and the ETACS-ECU.

NO : Go to Step 4.

STEP 4. Retest the system.

Check that the rear wiper operates continuously when the selector lever is moved to the R position during the rear wiper operation.

Q: Is the check result normal?

YES : Intermittent malfunction. NO : Replace the ETACS-ECU.

INSPECTION PROCEDURE 4: Rear washer does not work normally.

CIRCUIT OPERATION

The rear washer switch sends a signal through the column-ECU (incorporated in the column switch) to the ETACS-ECU. If the column-ECU sends a rear washer switch "ON" signal to the ETACS-ECU, the ETACS-ECU turns on the relay (incorporated in the ETACS-ECU), thus causing the windshield and rear washer motor to be turned on.

TECHNICAL DESCRIPTION (COMMENT)

If the rear washer does not work normally, the windshield and rear washer motor, the column switch (windshield wiper and washer switch) or the ETACS-ECU may be defective.

TROUBLESHOOTING HINTS

- The windshield and rear washer motor may be defective

- The column switch (windshield wiper, washer switch) may be defective

- The ETACS-ECU may be defective

DIAGNOSIS

Required Special Tools:

- MB991223: Harness Set

- MB992006: Extra Fine Probe

- MB991958: Scan Tool (M.U.T.-III Sub Assembly)

- MB991824: Vehicles communication interface (V.C.I.)

- MB991827: M.U.T.-III USB cable

- MB991911: M.U.T.-III Main harness B

STEP 1. Verify the windshield washers.

Q: Does the windshield washers operate?

YES : Go to Step 2.

NO : Refer to Inspection Procedure 7 "Windshield washer does not work".

STEP 2. Verify the rear wiper.

Q: Does the rear wiper operate?

YES : Go to Step 3.

NO : Refer to Inspection Procedure 1 "Rear wiper does not work".

STEP 3. Use the scan tool MB991958 to check if an ETACS-related diagnostic trouble code is set.

Connect the scan tool. Refer to GROUP 54A ETACS, "Diagnostic function".

Q: Is the diagnostic trouble code set?

YES : Diagnose the ETACS-ECU. NO : Go to Step 4.

STEP 4. Check the input signal related to the rear washer operation.

- Ignition switch: ACC

- Rear washer switch: ON

OK: Normal condition is displayed.

Q: Is the check result normal? NO : Go to Step 5.

YES : Refer to GROUP 54A − ETACS, Input signal procedures.

STEP 5. Check the washer motor.

- Disconnect the washer motor connector A-54.

- Fill the windshield washer tank with washer fluid.

- When battery voltage is applied between terminals 1 and 2, washer fluid should spray out.

Q: Does the washer motor operate normally?

YES : Go to Step 6.

NO : Replace the washer motor. Verify that the rear washer works normally.

STEP 6. Replace the ETACS-ECU, and then check its operation.

Replace the ETACS-ECU, and then check that the rear washer works normally.

- Replace the ETACS-ECU.

- Ignition switch: ON

- The rear washer should now work normally.

Q: Is the check result satisfactory?

YES : Intermittent malfunction. NO : Replace the Front-ECU.

ON-VEHICLE SERVICE

OPERATION CHECK OF REVERSE GEAR-LINKED OPERATION OF REAR WIPER

1. When the selector lever is moved to the "R" position with the rear wiper switch at the "INT" position, the wiper should operate twice or three times at low speed after approximately one second.

2. If not, carry out the troubleshooting.

CUSTOMIZATION FUNCTION

Using the ETACS system of scan tool MB991958, the following functions can be programmed. The programmed information is held even when the battery is disconnected.