Mitsubishi Outlander: DTC B1B1A, B1B1B, B1B20, B1B21, B1B22, B1B23

DTC B1B1A: Curtain Air Bag Module (LH) (Squib) System (Squib Circuit Open)

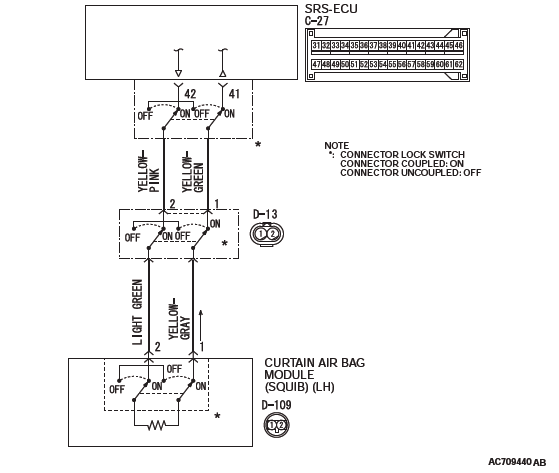

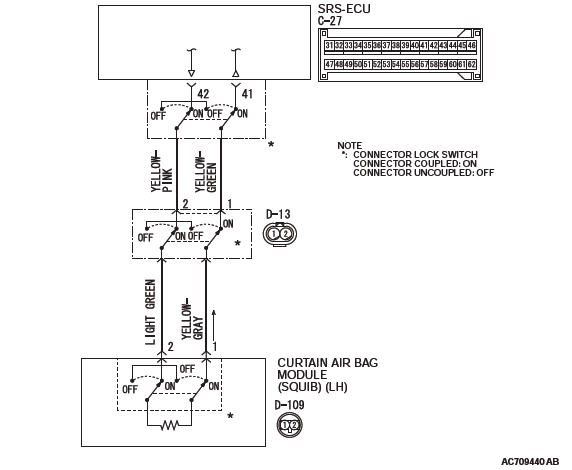

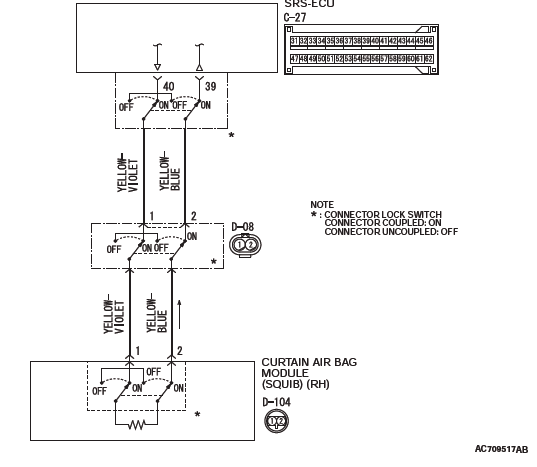

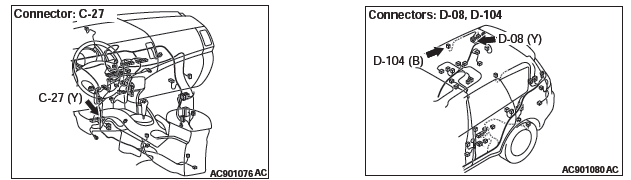

Curtain Air Bag Module (Squib) (LH) Circuit

CAUTION If DTC B1B1A is set in the SRS-ECU, always diagnose the CAN main bus line.

CIRCUIT OPERATION

- The SRS-ECU judges how severe a collision is by detecting signals from the side impact sensors installed on the lower side of the center pillar and at the quarter panel inner. If the impact is over a predetermined level, the SRS-ECU sends an ignition signal. At this time, if the side collision safing G-sensor is on, the SRS air bag will inflate.

The ignition signal is input to the curtain air bag module (LH) to inflate the curtain air bag.

DTC SET CONDITIONS

This DTC is set if there is abnormal resistance between the input terminals of the curtain air bag module (LH) (squib).

TROUBLESHOOTING HITS

- Open circuit in the curtain air bag module (LH) (squib) circuit

- Improper connector contact

- Malfunction of the SRS-ECU

DIAGNOSIS

Required Special Tools:

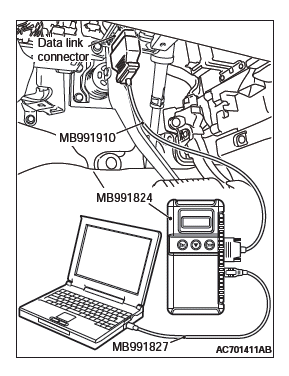

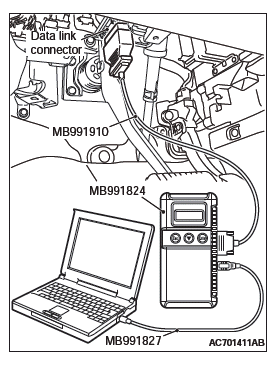

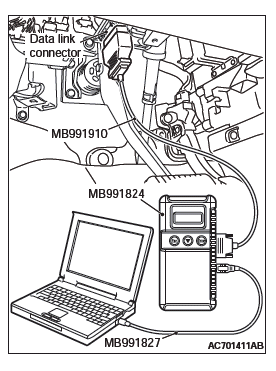

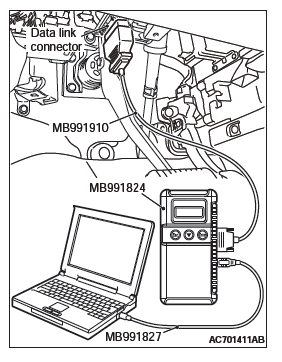

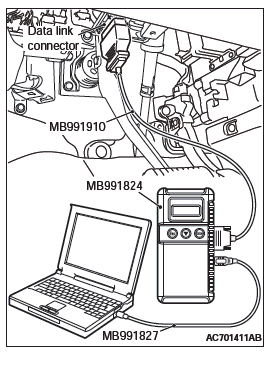

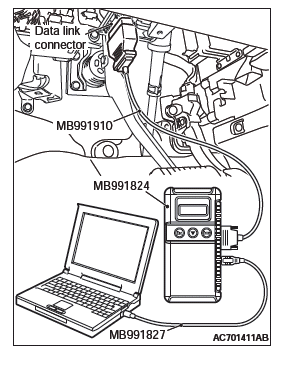

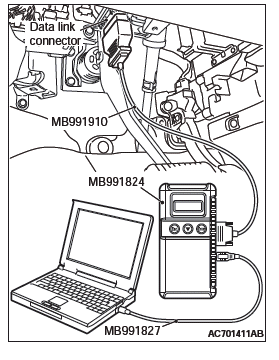

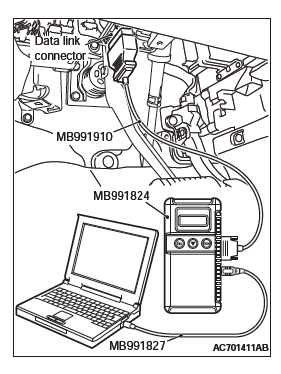

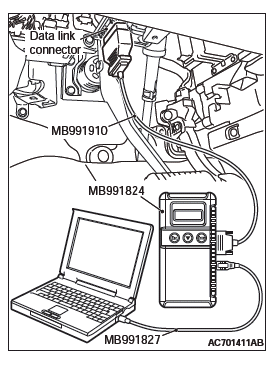

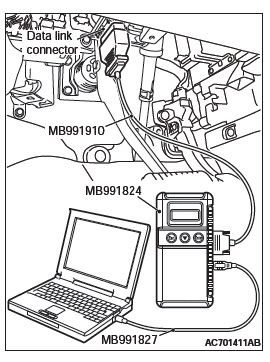

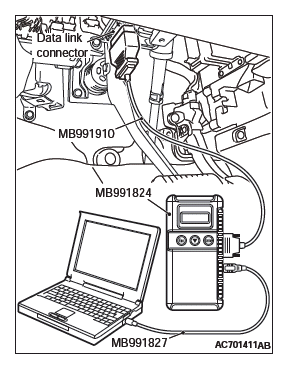

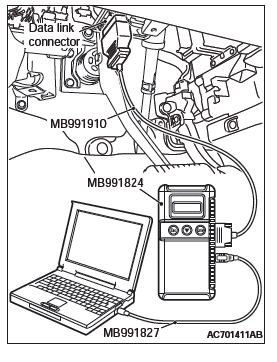

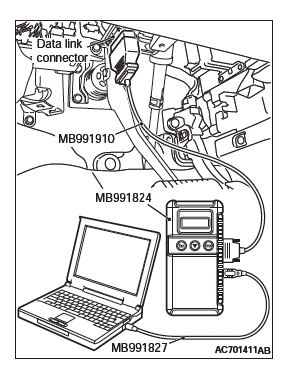

- MB991958: Scan Tool (M.U.T.-III Sub Assembly)

- MB991824: Vehicle Communication Interface (V.C.I.)

- MB991827: M.U.T.-III USB Cable

- MB991910: M.U.T.-III Main Harness A (Vehicles with CAN Communication System)

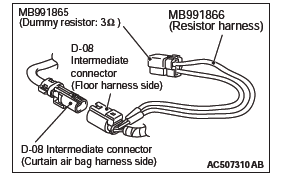

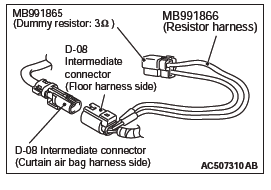

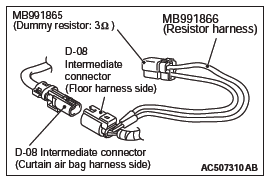

- MB991865: Dummy resistor

- MB991866: Resister harness

- MB991884: Resister harness

STEP 1. Using scan tool MB991958, diagnose the CAN bus line.

CAUTION To prevent damage to scan tool MB991958, always turn the ignition switch to the "LOCK" (OFF) position before connecting or disconnecting scan tool MB991958.

- Connect scan tool MB991958. Refer to "How to connect the scan tool".

- Turn the ignition switch to the "ON" position.

- Diagnose the CAN bus line.

- Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is the CAN bus line found to be normal?

YES : Go to Step 2.

NO : Repair the CAN bus line.

STEP 2. Recheck for diagnostic trouble code.

Check again if the DTC is set.

- Erase the DTC.

- Turn the ignition switch to "ON" position.

- Check if the DTC is set.

- Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is the DTC set?

YES : Go to Step 3.

NO : There is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Use Troubleshooting/Inspection Service Points − How to Cope with Intermittent Malfunctions).

STEP 3. Check by dummy resistor connection. (Using scan tool MB991958, read the diagnostic trouble code.)

- Disconnect the negative battery terminal.

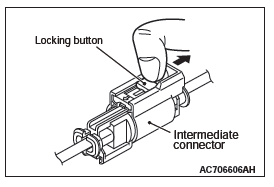

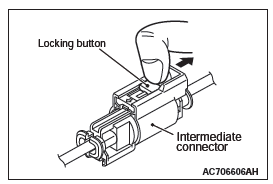

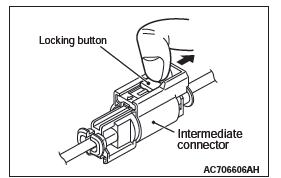

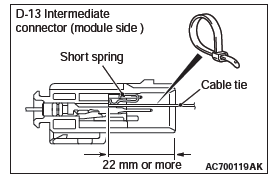

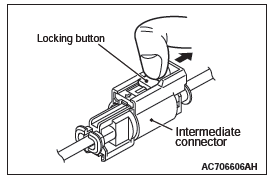

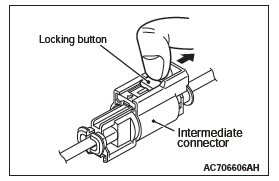

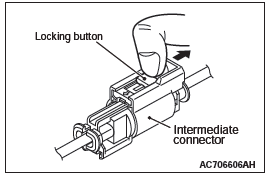

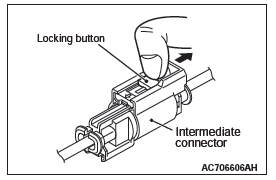

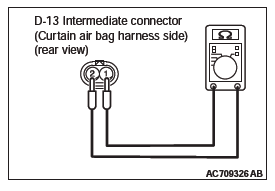

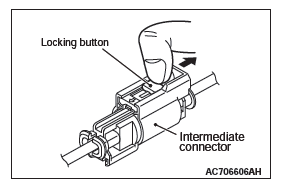

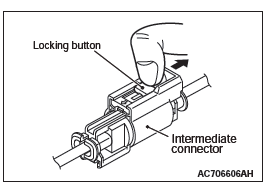

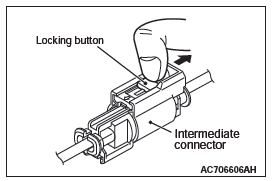

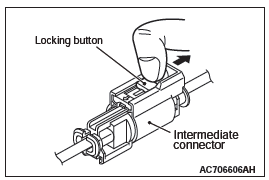

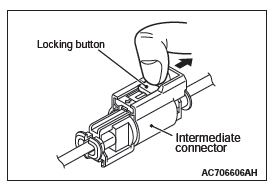

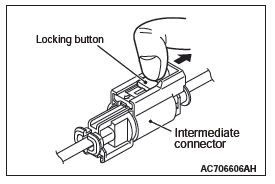

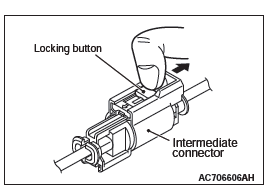

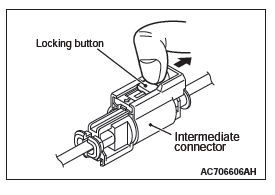

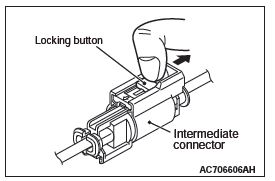

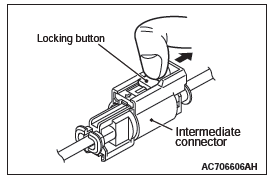

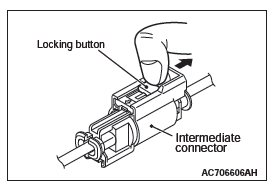

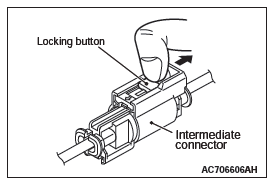

- Disconnect the D-13 intermediate connector, unlock the connector by sliding the locking button to the direction of the arrow as shown in the figure, and then disconnect the connector.

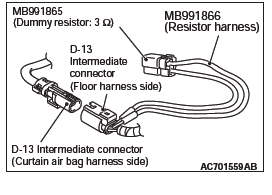

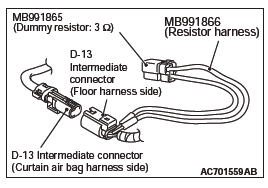

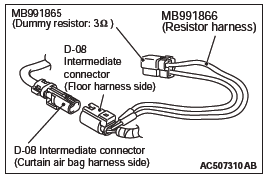

- Connect special tool MB991865 to special tool MB991866.

CAUTION Do not insert a probe into the terminal from its front side directly, as the connector contact pressure may be weakened.

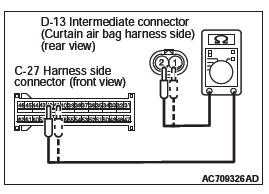

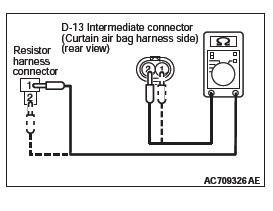

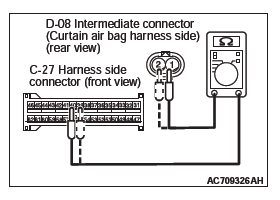

- Insert the probe of resistor harness, to which the dummy resistor is installed, from the back of D-13 intermediate connector (floor harness side).

- Connect the negative battery terminal.

- After erasing the diagnostic trouble code memory, check the diagnostic trouble code again.

- Disconnect the negative battery terminal.

Q: Is DTC B1B1A set?

YES : Go to Step 4.

NO : Go to Step 5.

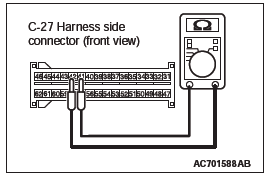

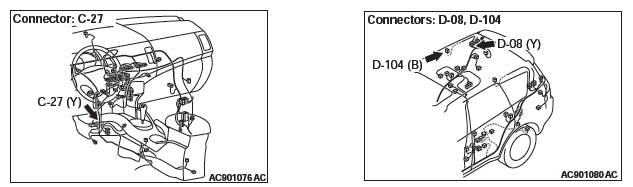

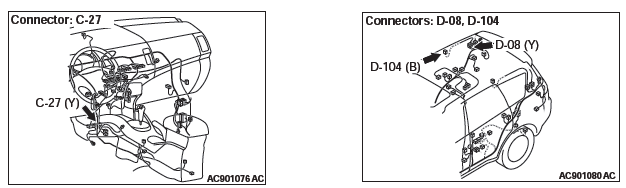

STEP 4. Resistance measurement at the C-27 SRS-ECU connector and the D-13 intermediate connector.

- Disconnect the negative battery terminal.

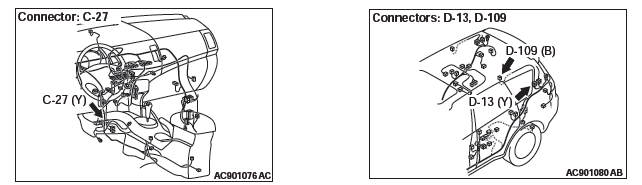

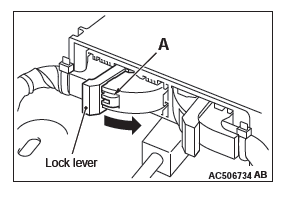

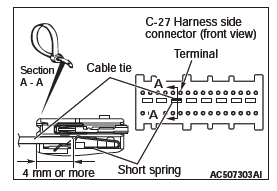

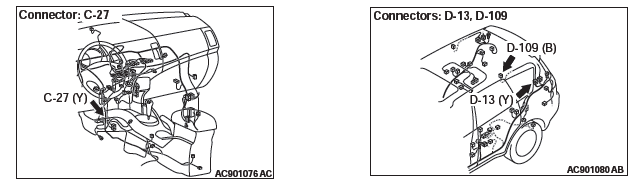

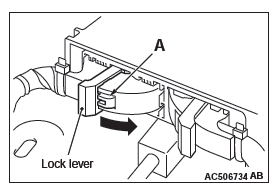

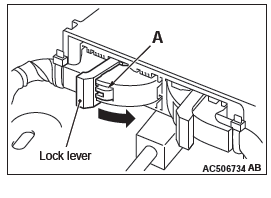

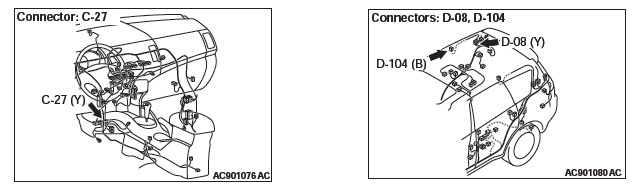

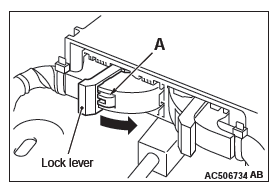

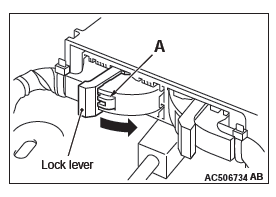

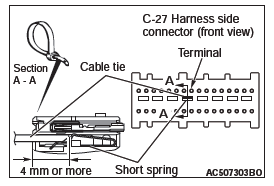

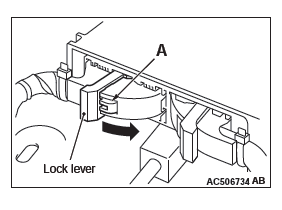

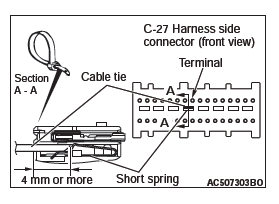

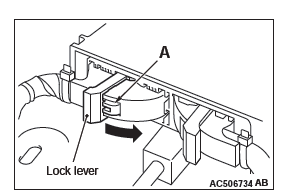

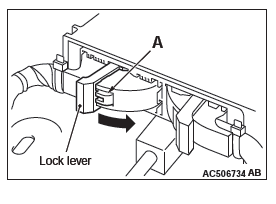

- While pushing the part "A" indicated in the figure of the harness side connector, turn the lock lever to the direction of the arrow to release the lock lever, and disconnect the C-27 SRS-ECU connector.

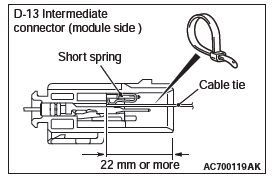

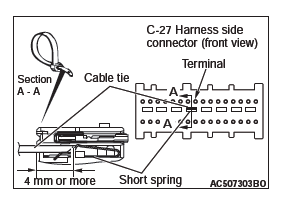

DANGER To release the SRS-ECU connector short spring in the following operations, disconnect this intermediate connector, and keep the squib circuit shorted.

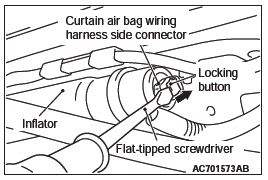

- Disconnect the D-13 intermediate connector, unlock the connector by sliding the locking button to the direction of the arrow as shown in the figure, and then disconnect the connector.

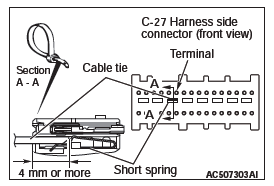

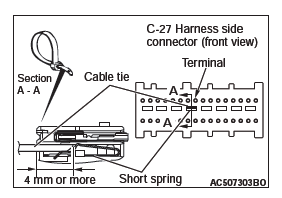

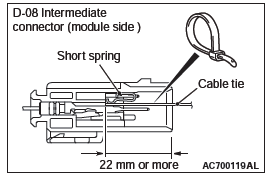

CAUTION The short spring may not be released due to the insufficient insertion. Therefore, insert the insulator for 4 mm (0.6 inch) or more.

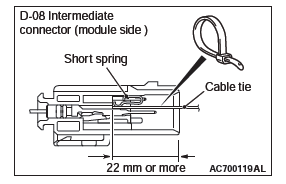

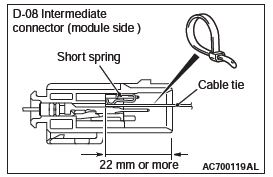

- Insert a cable tie [3 mm (0.12 inch) wide, 0.5 mm (0.02 inch) thick] between terminal 41, 42 and the short spring to release the short spring.

CAUTION Do not insert a probe into the terminal from D-13 intermediate connector front side directly, as the connector contact pressure may be weakened.

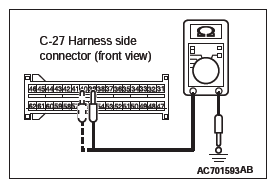

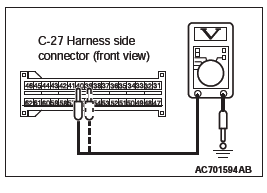

- Check for continuity between the following terminals. It should be less than 2 ohms.

- SRS-ECU connector C-27 (terminal No.41) and the intermediate connector D-13 (terminal No.1)

- SRS-ECU connector C-27 (terminal No.42) and the intermediate connector D-13 (terminal No.2)

Q: Does continuity exist?

YES : Go to Step 6.

NO : Repair the wiring harness between the C-27 harness side connector terminal No. 41, 42 and the D-13 intermediate connector (floor harness side) terminal No. 1, 2.

STEP 5. Resistance measurement at the D-13 intermediate connector terminal No. 1, 2 and the D-109 curtain air bag module harness side connector terminal No. 1, 2.

- Disconnect the negative battery terminal.

DANGER To prevent the air bag from deploying unintentionally, disconnect the curtain air bag module connector D-109 to short the squib circuit.

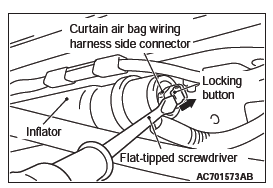

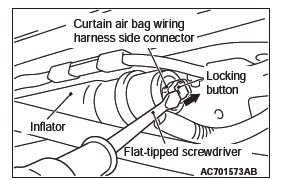

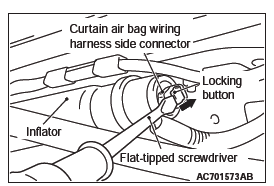

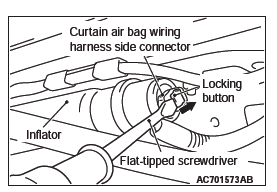

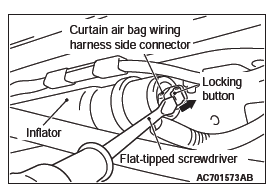

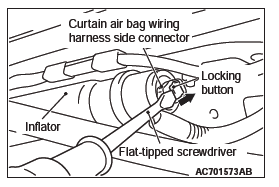

- Disconnect curtain air bag module (LH) D-109. Use a flat-tipped screwdriver to unlock the locking button at the harness side connector by withdrawing it toward you in two stages, and then disconnect the connector.

- Disconnect the D-13 intermediate connector, unlock the connector by sliding the locking button to the direction of the arrow as shown in the figure, and then disconnect the connector.

- Because the short spring is installed to the D-13 intermediate connector (curtain air bag harness side), insert a cable tie [3 mm (0.12 inch) wide, 0.5 mm (0.02 inch) thick] between terminals 1, 2 and the short spring to release the short spring.

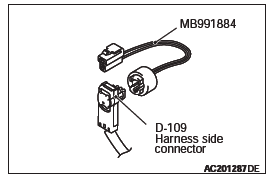

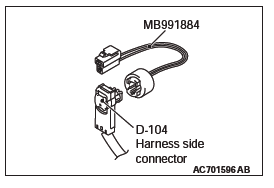

- Connect special tool MB991884 to the removed D-109 harness side connector.

CAUTION Do not insert a probe into the terminal from D-13 intermediate connector front side directly, as the connector contact pressure may be weakened.

- Check for continuity between the following terminals. It should be less than 2 ohms.

- Intermediate connector D-13 (terminal No.1) and resistor harness connector terminal No.2)

- Intermediate connector D-13 (terminal No.2) and resistor harness connector terminal No.1)

Q: Is the check result normal?

YES : Replace the curtain air bag module (squib).

NO : Repair the wiring harness.

STEP 6. Recheck for diagnostic trouble code.

Check again if the DTC is set.

- Erase the DTC.

- Turn the ignition switch to the "ON" position.

- Check if the DTC is set.

- Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is DTC B1B1A set?

YES : Replace SRS-ECU.

NO : Intermittent Malfunction (Refer to GROUP 00, How to Use Troubleshooting/Inspection Service Points − How to Cope with Intermittent Malfunction).

DTC B1B1B: Curtain Air Bag Module (LH) (Squib) System (Short Circuit between Squib Circuit Terminals)

Curtain Air Bag Module (Squib) (LH) Circuit

CAUTION If DTC B1B1B is set in the SRS-ECU, always diagnose the CAN main bus line.

CIRCUIT OPERATION

- The SRS-ECU judges how severe a collision is by detecting signals from the side impact sensors installed on the lower side of the center pillar and at the quarter panel inner. If the impact is over a predetermined level, the SRS-ECU sends an ignition signal. At this time, if the side collision safing G-sensor is on, the SRS air bag will inflate.

- The ignition signal is input to the curtain air bag module (LH) to inflate the curtain air bag.

DTC SET CONDITIONS

This DTC is set if there is abnormal resistance between the input terminals of the curtain air bag module (LH) (squib).

TROUBLESHOOTING HITS

- Improper engaged connector or defective short spring*

- Short circuit between the curtain air bag module (LH) (squib) circuit terminals

- Damaged connector(s)

- Malfunction of the SRS-ECU

NOTE: *: The squib circuit connectors integrate a "short" spring (which prevents the air bag from deploying unintentionally due to static electricity by shorting the positive wire to the ground wire in the squib circuit when the connectors are disconnected). Therefore, if connector C-27, D-13 or D-109 is damaged or improperly engaged, the short spring may not be released when the connector is connected.

DIAGNOSIS

Required Special Tools:

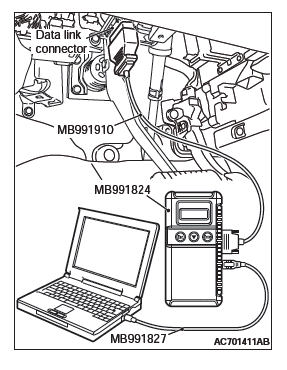

- MB991958: Scan Tool (M.U.T.-III Sub Assembly)

- MB991824: Vehicle Communication Interface (V.C.I.)

- MB991827: M.U.T.-III USB Cable

- MB991910: M.U.T.-III Main Harness A (Vehicles with CAN Communication System)

- MB991865: Dummy resistor

- MB991866: Resister harness

STEP 1. Using scan tool MB991958, diagnose the CAN bus line.

CAUTION To prevent damage to scan tool MB991958, always turn the ignition switch to the "LOCK" (OFF) position before connecting or disconnecting scan tool MB991958.

- Connect scan tool MB991958. Refer to "How to connect the scan tool".

- Turn the ignition switch to the "ON" position.

- Diagnose the CAN bus line.

- Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is the CAN bus line found to be normal?

YES : Go to Step 2.

NO : Repair the CAN bus line.

STEP 2. Recheck for diagnostic trouble code.

Check again if the DTC is set.

- Erase the DTC.

- Turn the ignition switch to "ON" position.

- Check if the DTC is set.

- Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is the DTC set?

YES : Go to Step 3.

NO : There is an intermittent malfunction such as poor engaged connector(s) or open circuit.

STEP 3. Check SRS-ECU connector C-27, curtain air bag module (LH) connector D-109 and intermediate connector D-13. (Using scan tool MB991958, read the diagnostic trouble code.)

- Disconnect the negative battery terminal.

- While pushing the part "A" indicated in the figure of the harness side connector, turn the lock lever to the direction of the arrow to release the lock lever, and disconnect the C-27 SRS-ECU connector. Then connect the connector.

- Disconnect the D-109 connectors, and then reconnect it.

Use a flat-tipped (−) screwdriver to pull out the D-109 curtain air bag module harness side connector locking button toward the arrow direction, release the lock, and then disconnect the connector.

- Disconnect the D-13 connector's, and then reconnect them.

Unlock the connector by sliding the locking button to the direction of the arrow as shown in the figure, and then disconnect the connector.

- Connect the negative battery terminal.

- After erasing the diagnostic trouble code memory, check the diagnostic trouble code again.

- Disconnect the negative battery terminal.

Q: Is DTC B1B1B set?

YES : Go to Step 4.

NO : Intermittent Malfunction.

STEP 4. Check by dummy resistor connection. (Using scan tool MB991958, read the diagnostic trouble code.)

- Disconnect the negative battery terminal.

- Disconnect the D-13 intermediate connector, unlock the connector by sliding the locking button to the direction of the arrow as shown in the figure, and then disconnect the connector.

- Connect special tool MB991865 to special tool MB991866.

CAUTION Do not insert a probe into the terminal from its front side directly, as the connector contact pressure may be weakened.

- Insert the probe of resistor harness, to which the dummy resistor is installed, from the back of D-13 intermediate connector (floor harness side).

- Connect the negative battery terminal.

- After erasing the diagnostic trouble code memory, check the diagnostic trouble code again.

Q: Is DTC B1B1B set?

YES : Go to Step 5.

NO : Go to Step 6.

STEP 5. Resistance measurement at the C-27 SRS-ECU connector.

- Disconnect the negative battery terminal.

- While pushing the part "A" indicated in the figure of the harness side connector, turn the lock lever to the direction of the arrow to release the lock lever, and disconnect the C-27 SRS-ECU connector.

DANGER To prevent the air bag from deploying unintentionally, disconnect the intermediate connector D-13 to short the squib circuit.

- Disconnect the D-13 intermediate connector, unlock the connector by sliding the locking button to the direction of the arrow as shown in the figure, and then disconnect the connector.

CAUTION The short spring may not be released due to the insufficient insertion. Therefore, insert the insulator for 4 mm (0.6 inch) or more.

- Insert a cable tie [3 mm (0.12 inch) wide, 0.5 mm (0.02 inch) thick] between terminal 41, 42 and the short spring to release the short spring.

- Check for continuity between the C-27 wiring harness side

connector terminal No. 41 and No. 42.

It should be open circuit.

Q: Is it open circuit?

YES : Go to Step 7.

NO : Repair the wiring harness.

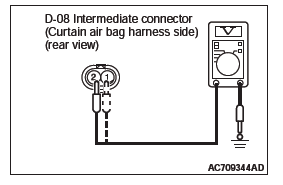

STEP 6. Short circuit check between the D-109 curtain air bag module harness side connector and the D-13 intermediate harness.

- Disconnect the negative battery terminal.

DANGER To prevent the air bag from deploying unintentionally, disconnect the curtain air bag module connector D-109 to short the squib circuit.

- Disconnect curtain air bag module (LH) D-109. Use a flat-tipped screwdriver to unlock the locking button at the harness side connector by withdrawing it toward you in two stages, and then disconnect the connector.

- Disconnect the D-13 intermediate connector, unlock the connector by sliding the locking button to the direction of the arrow as shown in the figure, and then disconnect the connector.

- Because the short spring is installed to the D-13 intermediate connector (curtain air bag harness side), insert a cable tie [3 mm (0.12 inch) wide, 0.5 mm (0.02 inch) thick] between terminals 1, 2 and the short spring to release the short spring.

CAUTION Do not insert a probe into the terminal from its front side directly, as the connector contact pressure may be weakened.

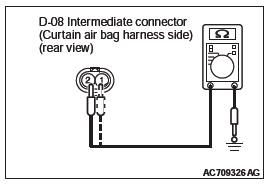

- Check for continuity between the D-13 intermediate

connector (curtain air bag harness side) terminal No. 1 and

No. 2.

It should be open circuit.

Q: Is it open circuit?

YES : Replace the curtain air bag module (LH). Then go to Step 7.

NO : Repair the wiring harness.

STEP 7. Recheck for diagnostic trouble code.

Check again if the DTC is set.

- Erase the DTC.

- Turn the ignition switch to the "ON" position.

- Check if the DTC is set.

- Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is DTC B1B1B set?

YES : Replace SRS-ECU. NO : Intermittent Malfunction (Refer to GROUP 00, How to Use Troubleshooting/Inspection Service Points − How to Cope with Intermittent Malfunction).

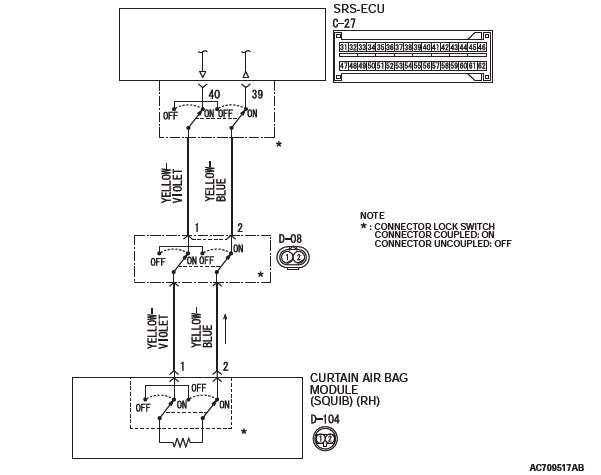

DTC B1B20: Curtain Air Bag Module (RH) (Squib) System (Shorted to Squib Circuit Ground)

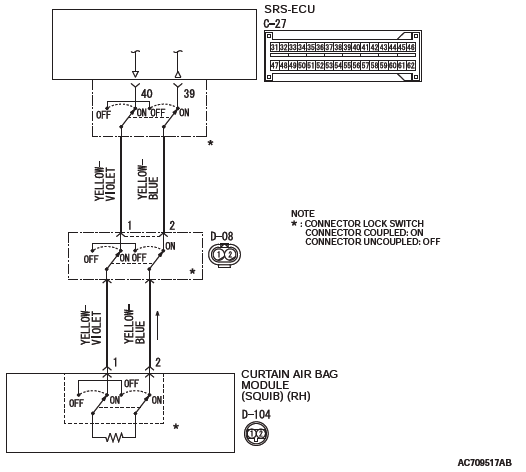

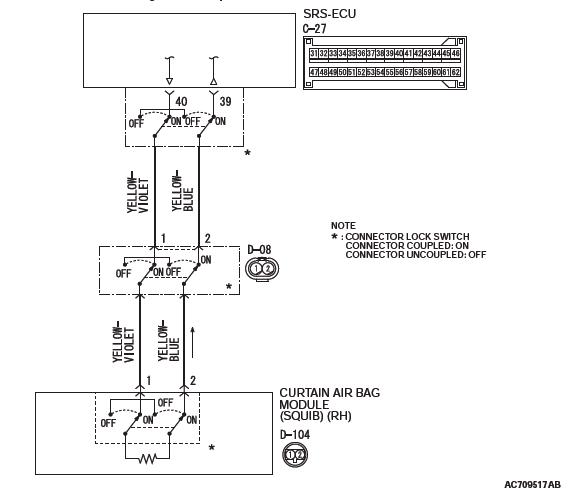

Curtain Air Bag Module (Squib) (RH) Circuit

CAUTION If DTC B1B20 is set in the SRS-ECU, always diagnose the CAN main bus line.

CIRCUIT OPERATION

- The SRS-ECU judges how severe a collision is by detecting signals from the side impact sensors installed on the lower side of the center pillar and at the quarter panel inner. If the impact is over a predetermined level, the SRS-ECU sends an ignition signal. At this time, if the side collision safing G-sensor is on, the SRS air bag will inflate.

- The ignition signal is input to the curtain air bag module (RH) to inflate the curtain air bag.

DTC SET CONDITIONS

This DTC is set if there is abnormal resistance between the input terminals of the curtain air bag module (RH) (squib).

TROUBLESHOOTING HITS

- Damaged wiring harnesses or connectors

- Short to the ground in the curtain air bag module (RH) (squib) harness

- Malfunction of the SRS-ECU

DIAGNOSIS

Required Special Tools:

- MB991958: Scan Tool (M.U.T.-III Sub Assembly)

- MB991824: Vehicle Communication Interface (V.C.I.)

- MB991827: M.U.T.-III USB Cable

- MB991910: M.U.T.-III Main Harness A (Vehicles with CAN Communication System)

- MB991865: Dummy resistor

- MB991866: Resister harness

STEP 1. Using scan tool MB991958, diagnose the CAN bus line.

CAUTION To prevent damage to scan tool MB991958, always turn the ignition switch to the "LOCK" (OFF) position before connecting or disconnecting scan tool MB991958.

- Connect scan tool MB991958. Refer to "How to connect the scan tool".

- Turn the ignition switch to the "ON" position.

- Diagnose the CAN bus line.

- Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is the CAN bus line found to be normal?

YES : Go to Step 2.

NO : Repair the CAN bus line.

STEP 2. Recheck for diagnostic trouble code.

Check again if the DTC is set.

- Erase the DTC.

- Turn the ignition switch to "ON" position.

- Check if the DTC is set.

- Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is the DTC set?

YES : Go to Step 3.

NO : There is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Use Troubleshooting/Inspection Service Points − How to Cope with Intermittent Malfunctions).

STEP 3. Check by dummy resistor connection. (Using scan tool MB991958, read the diagnostic trouble code.)

- Disconnect the negative battery terminal.

- Disconnect the D-08 intermediate connector, unlock the connector by sliding the locking button to the direction of the arrow as shown in the figure, and then disconnect the connector.

- Connect special tool MB991865 to special tool MB991866.

CAUTION Do not insert a probe into the terminal from its front side directly, as the connector contact pressure may be weakened.

- Insert the probe of resistor harness, to which the dummy resistor is installed, from the back of D-08 intermediate connector (floor harness side).

- Connect the negative battery terminal.

- After erasing the diagnostic trouble code memory, check the diagnostic trouble code again.

- Disconnect the negative battery terminal.

Q: Is DTC B1B20 set?

YES : Go to Step 4.

NO : Go to Step 5.

STEP 4. Resistance measurement at the C-27 SRS-ECU connector

- Disconnect the negative battery terminal.

- While pushing the part "A" indicated in the figure of the harness side connector, turn the lock lever to the direction of the arrow to release the lock lever, and disconnect the C-27 SRS-ECU connector.

DANGER To prevent the air bag from deploying unintentionally, disconnect the intermediate connector D-08 to short the squib circuit.

- Disconnect the D-08 intermediate connector, unlock the connector by sliding the locking button to the direction of the arrow as shown in the figure, and then disconnect the connector.

CAUTION The short spring may not be released due to the insufficient insertion. Therefore, insert the insulator for 4 mm (0.6 inch) or more.

- Insert a cable tie [3 mm (0.12 inch) wide, 0.5 mm (0.02 inch) thick] between terminal 39, 40 and the short spring to release the short spring.

- Check for continuity between C-27 wiring harness side

connector terminal No. 39, 40 and body ground.

It should be open circuit.

Q: Is it open circuit?

YES : Go to Step 6.

NO : Repair the wiring harness.

STEP 5. Resistance measurement at the D-08 intermediate connector.

- Disconnect the negative battery terminal.

DANGER To prevent the air bag from deploying unintentionally, disconnect the curtain air bag module connector D-104 to short the squib circuit.

- Disconnect curtain air bag module (RH) D-104. Use a flat-tipped screwdriver to unlock the locking button at the harness side connector by withdrawing it toward you in two stages, and then disconnect the connector.

- Disconnect the D-08 intermediate connector, unlock the connector by sliding the locking button to the direction of the arrow as shown in the figure, and then disconnect the connector.

- Because the short spring is installed to the D-08 intermediate connector (curtain air bag harness side), insert a cable tie [3 mm (0.12 inch) wide, 0.5 mm (0.02 inch) thick] between terminals 1, 2 and the short spring to release the short spring.

CAUTION Do not insert a probe into the terminal from its front side directly as the connector contact pressure may be weakened.

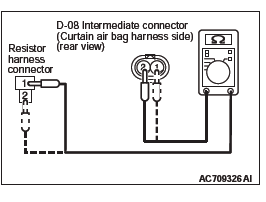

- Check for continuity between the D-08 intermediate

connector (module side) terminal No. 1, 2 and the body

ground.

It should be open circuit.

Q: Is it open circuit?

YES : Replace the curtain air bag module (squib).

NO : Repair the wiring harness.

STEP 6. Recheck for diagnostic trouble code.

Check again if the DTC is set.

- Erase the DTC.

- Turn the ignition switch to the "ON" position.

- Check if the DTC is set.

- Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is DTC B1B20 set?

YES : Replace SRS-ECU. NO : Intermittent Malfunction (Refer to GROUP 00, How to Use Troubleshooting/Inspection Service Points − How to Cope with Intermittent Malfunction).

DTC B1B21: Curtain Air Bag Module (RH) (Squib) System (Shorted to Squib Circuit Power Supply)

Curtain Air Bag Module (Squib) (RH) Circuit

CAUTION If DTC B1B21 is set in the SRS-ECU, always diagnose the CAN main bus line.

CIRCUIT OPERATION

- The SRS-ECU judges how severe a collision is by detecting signals from the side impact sensors installed on the lower side of the center pillar and at the quarter panel inner. If the impact is over a predetermined level, the SRS-ECU sends an ignition signal. At this time, if the side collision safing G-sensor is on, the SRS air bag will inflate.

- The ignition signal is input to the curtain air bag module (RH) to inflate the curtain air bag.

DTC SET CONDITIONS

This DTC is set if there is abnormal resistance between the input terminals of the curtain air bag module (RH) (squib).

TROUBLESHOOTING HITS

- Damaged wiring harnesses or connectors

- Short to the power supply in the curtain air bag module (RH) (squib) harness

- Malfunction of the SRS-ECU

DIAGNOSIS

Required Special Tools:

- MB991958: Scan Tool (M.U.T.-III Sub Assembly)

- MB991824: Vehicle Communication Interface (V.C.I.)

- MB991827: M.U.T.-III USB Cable

- MB991910: M.U.T.-III Main Harness A (Vehicles with CAN Communication System)

- MB991865: Dummy resistor

- MB991866: Resister harness

STEP 1. Using scan tool MB991958, diagnose the CAN bus line.

CAUTION To prevent damage to scan tool MB991958, always turn the ignition switch to the "LOCK" (OFF) position before connecting or disconnecting scan tool MB991958.

- Connect scan tool MB991958. Refer to "How to connect the scan tool".

- Turn the ignition switch to the "ON" position.

- Diagnose the CAN bus line.

- Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is the CAN bus line found to be normal?

YES : Go to Step 2.

NO : Repair the CAN bus line (Refer to GROUP 54C, Diagnosis).

STEP 2. Recheck for diagnostic trouble code.

Check again if the DTC is set.

- Erase the DTC.

- Turn the ignition switch to "ON" position.

- Check if the DTC is set.

- Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is the DTC set?

YES : Go to Step 3.

NO : There is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Use Troubleshooting/Inspection Service Points − How to Cope with Intermittent Malfunctions).

STEP 3. Check by dummy resistor connection. (Using scan tool MB991958, read the diagnostic trouble code.)

- Disconnect the negative battery terminal.

- Disconnect the D-08 intermediate connector, unlock the connector by sliding the locking button to the direction of the arrow as shown in the figure, and then disconnect the connector.

- Connect special tool MB991865 to special tool MB991866.

CAUTION Do not insert a probe into the terminal from its front side directly, as the connector contact pressure may be weakened.

- Insert the probe of resistor harness, to which the dummy resistor is installed, from the back of D-08 intermediate connector (floor harness side).

- Connect the negative battery terminal.

- After erasing the diagnostic trouble code memory, check the diagnostic trouble code again.

- Disconnect the negative battery terminal.

Q: Is DTC B1B21 set?

YES : Go to Step 4.

NO : Go to Step 5.

STEP 4. Voltage measurement at the C-27 SRS-ECU connector.

- Disconnect the negative battery terminal.

- While pushing the part "A" indicated in the figure of the harness side connector, turn the lock lever to the direction of the arrow to release the lock lever, and disconnect the C-27 SRS-ECU connector.

DANGER To prevent the air bag from deploying unintentionally, disconnect the intermediate connector D-08 to short the squib circuit.

- Disconnect the D-08 intermediate connector, unlock the connector by sliding the locking button to the direction of the arrow as shown in the figure, and then disconnect the connector.

CAUTION The short spring may not be released due to the insufficient insertion. Therefore, insert the insulator for 4 mm (0.6 inch) or more.

- Insert a cable tie [3 mm (0.12 inch) wide, 0.5 mm (0.02 inch) thick] between terminal 39, 40 and the short spring to release the short spring.

- Connect the negative battery terminal.

- Ignition switch: ON

- Measure the voltage between the C-27 wiring harness side

connector terminal No. 39, 40 and body ground.

Voltage should measure 1 volt or less.

Q: Is the measured voltage within the specified range?

YES : Go to Step 6.

NO : Repair the wiring harness.

STEP 5. Voltage measurement at the D-08 intermediate connector.

- Disconnect the negative battery terminal.

DANGER To prevent the air bag from deploying unintentionally, disconnect the curtain air bag module connector D-104 to short the squib circuit.

- Disconnect curtain air bag module (RH) D-104. Use a flat-tipped screwdriver to unlock the locking button at the harness side connector by withdrawing it toward you in two stages, and then disconnect the connector.

- Disconnect the D-08 intermediate connector, unlock the connector by sliding the locking button to the direction of the arrow as shown in the figure, and then disconnect the connector.

- Because the short spring is installed to the D-08 intermediate connector (curtain air bag harness side), insert a cable tie [3 mm (0.12 inch) wide, 0.5 mm (0.02 inch) thick] between terminals 1, 2 and the short spring to release the short spring.

- Connect the negative battery terminal.

- Ignition switch: ON

CAUTION Do not insert a probe into the terminal from its front side directly, as the connector contact pressure may be weakened.

- Check for continuity between the D-08 intermediate

connector (curtain air bag harness side) terminal No. 1, 2

and the body ground.

Voltage should measure 1 volt or less.

Q: Is the measured voltage within the specified range?

YES : Replace the curtain air bag module (squib).

NO : Repair the wiring harness.

STEP 6. Recheck for diagnostic trouble code.

Check again if the DTC is set.

- Erase the DTC.

- Turn the ignition switch to the "ON" position.

- Check if the DTC is set.

- Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is DTC B1B21 set?

YES : Replace SRS-ECU.

NO : Intermittent Malfunction.

DTC B1B22: Curtain Air Bag Module (RH) (Squib) System (Squib Circuit Open)

Curtain Air Bag Module (Squib) (RH) Circuit

CAUTION If DTC B1B22 is set in the SRS-ECU, always diagnose the CAN main bus line.

CIRCUIT OPERATION

- The SRS-ECU judges how severe a collision is by detecting signals from the side impact sensors installed on the lower side of the center pillar and at the quarter panel inner. If the impact is over a predetermined level, the SRS-ECU sends an ignition signal. At this time, if the side collision safing G-sensor is on, the SRS air bag will inflate.

- The ignition signal is input to the curtain air bag module (RH) to inflate the curtain air bag.

DTC SET CONDITIONS

This DTC is set if there is abnormal resistance between the input terminals of the curtain air bag module (RH) (squib).

TROUBLESHOOTING HITS

- Open circuit in the curtain air bag module (RH) (squib) circuit

- Improper connector contact

- Malfunction of the SRS-ECU

DIAGNOSIS

Required Special Tools:

- MB991958: Scan Tool (M.U.T.-III Sub Assembly)

- MB991824: Vehicle Communication Interface (V.C.I.)

- MB991827: M.U.T.-III USB Cable

- MB991910: M.U.T.-III Main Harness A (Vehicles with CAN Communication System)

- MB991865: Dummy resistor

- MB991866: Resister harness

- MB991884: Resister harness

STEP 1. Using scan tool MB991958, diagnose the CAN bus line.

CAUTION To prevent damage to scan tool MB991958, always turn the ignition switch to the "LOCK" (OFF) position before connecting or disconnecting scan tool MB991958.

- Connect scan tool MB991958. Refer to "How to connect the scan tool".

- Turn the ignition switch to the "ON" position.

- Diagnose the CAN bus line.

- Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is the CAN bus line found to be normal?

YES : Go to Step 2.

NO : Repair the CAN bus line.

STEP 2. Recheck for diagnostic trouble code.

Check again if the DTC is set.

- Erase the DTC.

- Turn the ignition switch to "ON" position.

- Check if the DTC is set.

- Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is the DTC set?

YES : Go to Step 3.

NO : There is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Use Troubleshooting/Inspection Service Points − How to Cope with Intermittent Malfunctions).

STEP 3. Check by dummy resistor connection. (Using scan tool MB991958, read the diagnostic trouble code.)

- Disconnect the negative battery terminal.

- Disconnect the D-08 intermediate connector, unlock the connector by sliding the locking button to the direction of the arrow as shown in the figure, and then disconnect the connector.

- Connect special tool MB991865 to special tool MB991866.

CAUTION Do not insert a probe into the terminal from its front side directly, as the connector contact pressure may be weakened.

- Insert the probe of resistor harness, to which the dummy resistor is installed, from the back of D-08 intermediate connector (floor harness side).

- Connect the negative battery terminal.

- After erasing the diagnostic trouble code memory, check the diagnostic trouble code again.

- Disconnect the negative battery terminal.

Q: Is DTC B1B22 set?

YES : Go to Step 4.

NO : Go to Step 5.

STEP 4. Resistance measurement at the C-27 SRS-ECU connector and the D-08 intermediate connector.

- Disconnect the negative battery terminal.

- While pushing the part "A" indicated in the figure of the harness side connector, turn the lock lever to the direction of the arrow to release the lock lever, and disconnect the C-27 SRS-ECU connector.

DANGER To prevent the air bag from deploying unintentionally, disconnect the intermediate connector D-08 to short the squib circuit.

- Disconnect the D-08 intermediate connector, unlock the connector by sliding the locking button to the direction of the arrow as shown in the figure, and then disconnect the connector.

CAUTION The short spring may not be released due to the insufficient insertion. Therefore, insert the insulator for 4 mm (0.6 inch) or more.

- Insert a cable tie [3 mm (0.12 inch) wide, 0.5 mm (0.02 inch) thick] between terminal 39, 40 and the short spring to release the short spring.

CAUTION Do not insert a probe into the terminal from D-08 intermediate connector front side directly, as the connector contact pressure may be weakened.

- Check for continuity between the following terminals. It should be less than 2 ohms.

- SRS-ECU connector C-27 (terminal No.39) and the intermediate connector D-08 (terminal No.2)

- SRS-ECU connector C-27 (terminal No.40) and the intermediate connector D-08 (terminal No.1)

Q: Does continuity exist?

YES : Go to Step 6.

NO : Repair the wiring harness between the C-27 harness side connector terminal No. 39, 40 and the D-08 intermediate connector (floor harness side) terminal No. 2, 1.

STEP 5. Resistance measurement at the D-08 intermediate connector terminal No. 1, 2 and the D-104 curtain air bag module harness side connector terminal No. 1, 2.

- Disconnect the negative battery terminal.

DANGER To prevent the air bag from deploying unintentionally, disconnect the curtain air bag module connector D-104 to short the squib circuit.

- Disconnect curtain air bag module (RH) D-104. Use a flat-tipped screwdriver to unlock the locking button at the harness side connector by withdrawing it toward you in two stages, and then disconnect the connector.

- Disconnect the D-08 intermediate connector, unlock the connector by sliding the locking button to the direction of the arrow as shown in the figure, and then disconnect the connector.

- Because the short spring is installed to the D-08 intermediate connector (curtain air bag harness side), insert a cable tie [3 mm (0.12 inch) wide, 0.5 mm (0.02 inch) thick] between terminals 1, 2 and the short spring to release the short spring.

- Connect special tool MB991884 to the removed D-104 harness side connector.

CAUTION Do not insert a probe into the terminal from D-08 intermediate connector front side directly, as the connector contact pressure may be weakened.

- Check for continuity between the following terminals.

It should be less than 2 ohms.

- Intermediate connector D-08 (terminal No.1) and resistor harness connector terminal No.2)

- Intermediate connector D-08 (terminal No.2) and resistor harness connector terminal No.1)

Q: Is the check result normal?

YES : Replace the curtain air bag module (squib).

NO : Repair the wiring harness.

STEP 6. Recheck for diagnostic trouble code.

Check again if the DTC is set.

- Erase the DTC.

- Turn the ignition switch to the "ON" position.

- Check if the DTC is set.

- Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is DTC B1B22 set?

YES : Replace SRS-ECU. NO : Intermittent Malfunction (Refer to GROUP 00, How to Use Troubleshooting/Inspection Service Points − How to Cope with Intermittent Malfunction).

DTC B1B23: Curtain Air Bag Module (RH) (Squib) System (Short Circuit between Squib Circuit Terminals)

Curtain Air Bag Module (Squib) (RH) Circuit

CAUTION If DTC B1B23 is set in the SRS-ECU, always diagnose the CAN main bus line.

CIRCUIT OPERATION

- The SRS-ECU judges how severe a collision is by detecting signals from the side impact sensors installed on the lower side of the center pillar and at the quarter panel inner. If the impact is over a predetermined level, the SRS-ECU sends an ignition signal. At this time, if the side collision safing G-sensor is on, the SRS air bag will inflate.

- The ignition signal is input to the curtain air bag module (RH) to inflate the curtain air bag.

DTC SET CONDITIONS

This DTC is set if there is abnormal resistance between the input terminals of the curtain air bag module (RH) (squib).

TROUBLESHOOTING HITS

- Improper engaged connector or defective short spring*

- Short circuit between the curtain air bag module (RH) (squib) circuit terminals

- Damaged connector(s)

- Malfunction of the SRS-ECU

NOTE: *: The squib circuit connectors integrate a "short" spring (which prevents the air bag from deploying unintentionally due to static electricity by shorting the positive wire to the ground wire in the squib circuit when the connectors are disconnected). Therefore, if connector C-27, D-08 or D-104 is damaged or improperly engaged, the short spring may not be released when the connector is connected.

DIAGNOSIS

Required Special Tools:

- MB991958: Scan Tool (M.U.T.-III Sub Assembly)

- MB991824: Vehicle Communication Interface (V.C.I.)

- MB991827: M.U.T.-III USB Cable

- MB991910: M.U.T.-III Main Harness A (Vehicles with CAN Communication System)

- MB991865: Dummy resistor

- MB991866: Resister harness

STEP 1. Using scan tool MB991958, diagnose the CAN bus line.

CAUTION To prevent damage to scan tool MB991958, always turn the ignition switch to the "LOCK" (OFF) position before connecting or disconnecting scan tool MB991958.

- Connect scan tool MB991958. Refer to "How to connect the scan tool".

- Turn the ignition switch to the "ON" position.

- Diagnose the CAN bus line.

- Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is the CAN bus line found to be normal?

YES : Go to Step 2.

NO : Repair the CAN bus line.

STEP 2. Recheck for diagnostic trouble code.

Check again if the DTC is set.

- Erase the DTC.

- Turn the ignition switch to "ON" position.

- Check if the DTC is set.

- Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is the DTC set?

YES : Go to Step 3.

NO : There is an intermittent malfunction such as poor engaged connector(s) or open circuit (Refer to GROUP 00, How to Use Troubleshooting/Inspection Service Points − How to Cope with Intermittent Malfunctions).

STEP 3. Check SRS-ECU connector C-27, curtain air bag module (RH) connector D-104 and intermediate connector D-08. (Using scan tool MB991958, read the diagnostic trouble code.)

- Disconnect the negative battery terminal.

- While pushing the part "A" indicated in the figure of the harness side connector, turn the lock lever to the direction of the arrow to release the lock lever, and disconnect the C-27 SRS-ECU connector. Then connect the connector.

- Disconnect the D-104 connector, and then reconnect it. Use a flat-tipped (−) screwdriver to pull out the D-104 curtain air bag module harness side connector locking button toward the arrow direction, release the lock, and then disconnect the connector.

- Disconnect the D-08 connector's, and then reconnect them.

Unlock the connector by sliding the locking button to the direction of the arrow as shown in the figure, and then disconnect the connector.

- Connect the negative battery terminal.

- After erasing the diagnostic trouble code memory, check the diagnostic trouble code again.

- Disconnect the negative battery terminal.

Q: Is DTC B1B23 set?

YES : Go to Step 4.

NO : Intermittent Malfunction (Refer to GROUP 00, How to Use Troubleshooting/Inspection Service Points − How to Cope with Intermittent Malfunction).

STEP 4. Check by dummy resistor connection. (Using scan tool MB991958, read the diagnostic trouble code.)

- Disconnect the negative battery terminal.

- Disconnect the D-08 intermediate connector, unlock the connector by sliding the locking button to the direction of the arrow as shown in the figure, and then disconnect the connector.

- Connect special tool MB991865 to special tool MB991866.

CAUTION Do not insert a probe into the terminal from its front side directly, as the connector contact pressure may be weakened.

- Insert the probe of resistor harness, to which the dummy resistor is installed, from the back of D-08 intermediate connector (floor harness side).

- Connect the negative battery terminal.

- After erasing the diagnostic trouble code memory, check the diagnostic trouble code again.

Q: Is DTC B1B23 set?

YES : Go to Step 5.

NO : Go to Step 6.

STEP 5. Resistance measurement at the C-27 SRS-ECU connector.

- Disconnect the negative battery terminal.

- While pushing the part "A" indicated in the figure of the harness side connector, turn the lock lever to the direction of the arrow to release the lock lever, and disconnect the C-27 SRS-ECU connector.

DANGER To prevent the air bag from deploying unintentionally, disconnect the intermediate connector D-08 to short the squib circuit.

- Disconnect the D-08 intermediate connector, unlock the connector by sliding the locking button to the direction of the arrow as shown in the figure, and then disconnect the connector.

CAUTION

The short spring may not be released due to the insufficient

insertion. Therefore, inseREAD NEXT:

DTC B1B54: Seat Belt Buckle Switch (RH) Circuit (Ground Side) Shorted

DTC B1B55: Seat Belt Buckle Switch (RH) Circuit (Power Supply Side) Shorted

DTC B1B56: Seat Belt Buckle Switch (RH) Circuit Open

DTC B1B54, B1B55, B1B56, B1B70, B1B71, B1B72, B1B73, B1B75, B1B76, B1BA3,

B1BA4, B1BA5, B1BAA, B1BC7, B1BCF

DTC B1B54, B1B55, B1B56, B1B70, B1B71, B1B72, B1B73, B1B75, B1B76, B1BA3,

B1BA4, B1BA5, B1BAA, B1BC7, B1BCF

DTC B1C27: Side-air bag Module (LH) (Squib) System (Shorted to Squib

Circuit Ground)

Side-Airbag Module (Squib) (LH) Circuit

CAUTION

If DTC B1C27 is set in the SRS-ECU, always diagnose

the CAN bus

DTC B1C27, B1C28, B1C29, B1C2A, B1C2B, B1C2C, B1C2D, B1C2E

DTC B1C27, B1C28, B1C29, B1C2A, B1C2B, B1C2C, B1C2D, B1C2E

DTC B1C33: Driver's Lap Pre-tensioner (Squib) System (Shorted to Squib

Circuit Ground)

Driver's Lap pre-tensioner (Squib) Circuit

CAUTION

If DTC B1C33 is set in the SRS-ECU, always diagnose

the CAN

DTC B1C33, B1C34, B1C35, B1C36, B1C38, B1C39, B1C3A, B1C3B

DTC B1C33, B1C34, B1C35, B1C36, B1C38, B1C39, B1C3A, B1C3B

SEE MORE:

REMOVAL AND INSTALLATION

Removal steps

Cylinder head bolt

Cylinder head bolt washer

Cylinder head bolt & washer

assembly

Cylinder head assembly

Cylinder head gasket

Engine oil control valve (OCV) filter

Retainer lock

Valve spring retainer

Valve spring

Intake valve

Retainer lock

Va

Cylinder Head and Valves

Cylinder Head and Valves

DTC P0010: Intake Engine Oil Control Valve Circuit

CIRCUIT OPERATION

The intake engine oil control valve power is supplied

from the MFI relay (terminal No. 2).

The ECM controls ground intake engine oil control

valve by turning the power transistor in the

ECM "ON" and "OFF".

TECHNICAL DESCR

DTC P0010, P0011, P0013, P0014, P0016, P0017, P0031, P0032, P0037, P0038

DTC P0010, P0011, P0013, P0014, P0016, P0017, P0031, P0032, P0037, P0038