Mitsubishi Outlander: Engine Lubrication

General Information

The lubrication method is a fully force-fed, full-flow filtration type.

ENGINE OILS

WARNING

Prolonged and repeated contact with mineral oil will result in the removal of natural fats from the skin, leading to dryness, irritation and dermatitis. In addition, used engine oil contains potentially harmful contaminants which may cause skin cancer. Adequate means of skin protection and washing facilities must be provided.

Recommended Precautions

The most effective precaution is to prevent, as far as practical, the risk of skin contact with mineral oils i.e.

use enclosed systems for handling used engine oil and degrease components, where practical, before handling them.

Other precautions:

- Avoid prolonged and repeated contact with oil, particularly used engine oil.

- Wear protective clothing, including impervious gloves where practical.

- Avoid contaminating clothes with oil.

- Do not put oily rags in pockets.

- Do not wear heavily soiled clothing and oil-soaked foot-wear. Overalls must be cleaned regularly and kept separate from personal clothing.

- Where there is a risk of eye contact, eye protection should be worn i.e. chemical goggles or face shields. In addition, an eye wash facility should be provided.

- Obtain first aid treatment immediately for open cuts and wounds.

- Wash regularly with soap and water to ensure all oil is removed (skin cleansers and nail brushes will help). After cleaning, apply lotion, etc., containing lanolin to replace natural skin oils is advised.

- Do not use gasoline, kerosene, diesel fuel, gas oil, thinners or solvents for cleaning skin.

- Apply barrier creams before each work period.

- If skin disorders develop, obtain medical advice immediately.

Lubricants

ENGINE OIL

CAUTION

Never use nondetergent or straight mineral oil.

Use only engine oils displaying the ILSAC certification symbol ("Starburst" symbol) on the container.

If these oils are not available, an API classification SM can be used.

Service Specifications

Sealant

Special Tools

On-vehicle Service

ENGINE OIL CHECK

1. Pull out the engine oil dipstick, clean off the engine oil on the engine oil dipstick, and then reinsert the engine oil dipstick.

2. Pull out the engine oil dipstick, and check the engine oil level is within the marks on one side of the engine oil dipstick (engine cover side.)

NOTE:

- Checking the engine oil might be difficult shortly after stopping the engine or engine oil replacement.

- If difficult, take some time (approximately 30 seconds) and try again.

- Refer to the information label indicating the engine oil check process on the rocker cover.

3. Check that the engine oil is not excessively dirty, that there is no coolant or gasoline mixed in, and that it is sufficiently thick and slippery.

ENGINE OIL REPLACEMENT

1. Start the engine and allow it to warm up until the temperature of the coolant reaches 80 − 90ºC (176 − 194ºF).

WARNING

Use care as oil could be hot.

2. Remove the engine oil filler cap.

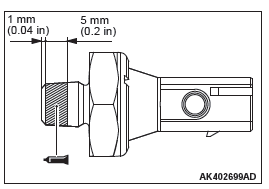

3. Remove the drain plug to drain oil.

4. Install a new drain plug gasket so that it faces in the direction shown in the illustration, and then tighten the drain plug to the specified torque.

Tightening torque: 39 +- 5 N*m (29 +- 3 ft-lb)

5. Refill the specified quantity of engine oil <2.4L ENGINE>.

Specified Engine Oil: Engine oils displaying the ILSAC certification symbol ("Starburst" symbol) or conforming to the API classification SM

Total quantity (Includes volume inside engine oil filter): 4.6 dm3 (4.82 quarts)

6. Refill the specified quantity of engine oil <3.0L ENGINE>.

Specified Engine Oil: Engine oils displaying the ILSAC certification symbol ("Starburst" symbol) or conforming to the API classification SM

Total quantity (Includes volume inside engine oil filter): 4.3 dm3 (4.52 quarts)

NOTE: SAE 5W-20 engine oil is strongly recommended for optimum fuel economy and cold starting.

7. Install the engine oil filler cap.

8. Let the engine run for a few minutes.

9. Stop the engine, and then check the oil level using the oil dipstick after a few minutes.

ENGINE OIL FILTER REPLACEMENT

Required Special Tools:

- MB991828: Oil Filter Wrench

- MB991396: Oil Filter Wrench

1. Start the engine and allow it to warm up until the temperature of the coolant reaches 80 − 90ºC (176 − 194ºF)

WARNING

Use care as oil could be hot.

2. Remove the engine oil filler cap.

3. Remove the drain plug to drain oil.

CAUTION

Cover the starter assembly with a rag to prevent the engine oil from adhering to the starter assembly, otherwise the starter assembly may be damaged <3.0L ENGINE>.

4. Use the respective tool in the following table to remove the engine oil filter.

5. Clean the filter bracket side mounting surface and ensure the old O-ring has been removed.

6. Apply a small amount of engine oil to the O-ring of the new oil filter.

CAUTION

Thoroughly remove the rag that was covering the starter because the inside of the engine compartment gets very hot <3.0L ENGINE>.

7. Screw on the oil filter by hand until it touches the surface of the flange and then tighten it with an oil filter wrench.

8. Install the drain plug and refill engine oil.

9. Rev the engine a few times, and check to be sure that no engine oil leaks at the oil filter.

OIL FILTER STUD REPLACEMENT <3.0L ENGINE>

Required Special Tool:

- MB992676: Oil Filter Stud Setter

1. Remove the engine oil filter.

2. Remove the oil filter stud using the screw extractor (Recommended tool: MB992684), or equivalent.

NOTE: This recommended tool is a component of the screw extractor set (MB992678).

3. Using special tool MB992676, install the new oil filter stud and tighten it to the specified torque.

Tightening torque: 49 +- 5 N*m (36 +- 3 in-lb)

4. Install the engine oil filter.

ENGINE OIL PRESSURE CHECK

CAUTION

Since sealant is applied to the thread of the engine oil pressure switch, take care not to damage the engine oil pressure switch when removing it.

2. Remove the engine oil pressure switch. <2.4L> <3.0L>

3. Install the engine oil pressure gauge.

NOTE: Use a 1/8 pipe thread adapter.

4. Run the engine to warm it.

5. After the engine has been warmed up, check that engine oil pressure is within the standard value.

Standard value:

At idle: 29 kPa (4.2 psi) or more

At 3,500 r/min: 294 − 686 kPa (43 − 100 psi)

6. Remove the engine oil pressure gauge.

7. Install the engine oil pressure switch.

<2.4L> <3.0L>

Engine Oil Pressure Switch

REMOVAL AND INSTALLATION <2.4L ENGINE>

Pre-removal Operation

- Engine Room Under Cover Front A, B Removal

- Intake Manifold Stay Removal

Post-installation Operation

- Intake Manifold Stay Installation

- Engine Room Under Cover Front A, B Installation

Removal steps

- Throttle body mounting bolts

- Engine oil pressure switch connector connection

- Engine oil pressure switch

Required Special Tool:

- MB992118: Oil Pressure Switch Wrench

REMOVAL SERVICE POINTS

THROTTLE BODY MOUNTING BOLTS REMOVAL

Remove the throttle body mounting bolts and put the throttle body aside so as not to interfere the oil pressure switch connector disconnection.

ENGINE OIL PRESSURE SWITCH REMOVAL

CAUTION

The sealant is applied to the bolt. Remove the bolt with care not to break it.

Use special tool MB992118 to remove the engine oil pressure switch.

INSTALLATION SERVICE POINT

ENGINE OIL PRESSURE SWITCH INSTALLATION

1. Apply sealant to the engine oil pressure switch thread.

Specified sealant: ThreeBond 1141J or equivalent

NOTE: Install the engine oil pressure switch immediately after applying sealant.

CAUTION

After the installation, until a sufficient period of time (one hour or more) elapses, do not apply the oil or water to the sealant application area or start the engine.

2. In the same manner as removal, use special tool MD992118 to tighten the engine oil pressure switch to the specified torque.

Tightening torque: 10 +- 2 N*m (87 +- 17 in−lb)

REMOVAL AND INSTALLATION <3.0L ENGINE>

Pre-removal Operation

- Engine Room Under Cover Front Removal

Post-installation Operation

- Engine Room Under Cover Front Installation

Removal steps

- Engine oil pressure switch connector connection

- Heat protector

- Engine oil pressure switch

Required Special Tool:

- MB992118: Oil Pressure Switch Wrench

REMOVAL SERVICE POINT

ENGINE OIL PRESSURE SWITCH REMOVAL

Use special tool MB992118 to remove the engine oil pressure switch.

INSTALLATION SERVICE POINT

ENGINE OIL PRESSURE SWITCH INSTALLATION

1. Apply sealant to the engine oil pressure switch thread.

Specified sealant: ThreeBond 1141J or equivalent

NOTE: Install the engine oil pressure switch immediately after applying sealant.

CAUTION

After the installation, until a sufficient period of time (one hour or more) elapses, do not apply the oil or water to the sealant application area or start the engine.

2. In the same manner as removal, use special tool MB992118 to tighten the engine oil pressure switch to the specified torque.

Tightening torque: 10 +- 2 N*m (87 +- 17 in−lb)